Electrical work involves a lot of risks, and LOTO (Lockout/Tagout) procedures are one of the key practices that help manage those risks. If you’re a contractor, understanding LOTO is crucial—not just to stay compliant, but to keep your crew safe on the job. LOTO procedures ensure that equipment is properly de-energized before any maintenance or repair work begins, reducing the risk of accidental shocks or arc flashes.

In this post, we’ll cover everything contractors need to know about LOTO, from the basics to best practices that will keep your team safe and your projects running smoothly.

What is Lockout/Tagout (LOTO)?

LOTO is a safety protocol used to control hazardous energy during equipment maintenance and repair. The goal is to ensure that machinery and electrical systems are completely de-energized and locked out, so there’s no chance of them accidentally powering up while work is in progress. Tagout refers to placing a visible tag on the equipment, indicating that it’s locked out and warning others not to activate it.

Why LOTO Procedures Matter in Electrical Work

In an industrial setting, the risks associated with electrical systems are high. If equipment is unexpectedly powered on, workers can be exposed to serious hazards, including electrical shock, arc flashes, or even fatal injuries. LOTO procedures provide a clear and reliable way to ensure that all equipment remains off while work is being performed.

Without proper LOTO, you’re leaving your team vulnerable to accidents that could be prevented with the right precautions in place.

The Essential Steps of a Lockout/Tagout Procedure

LOTO procedures involve several steps to make sure everything is done safely and correctly. Here’s a quick breakdown:

- Preparation: Identify the equipment that needs to be locked out and understand the type of energy involved.

- Shutdown: Power down the equipment using normal shutdown procedures.

- Isolation: Disconnect or isolate the energy sources to prevent re-energization.

- Lockout and Tagout: Place lockout devices on energy sources and apply warning tags to let others know the equipment is off-limits.

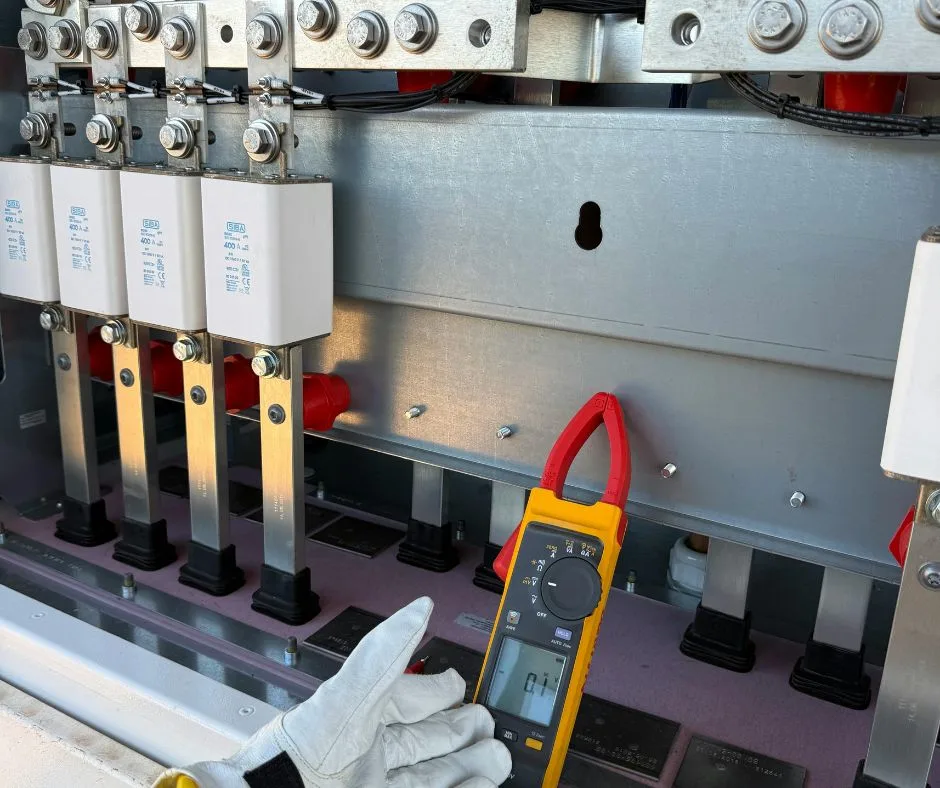

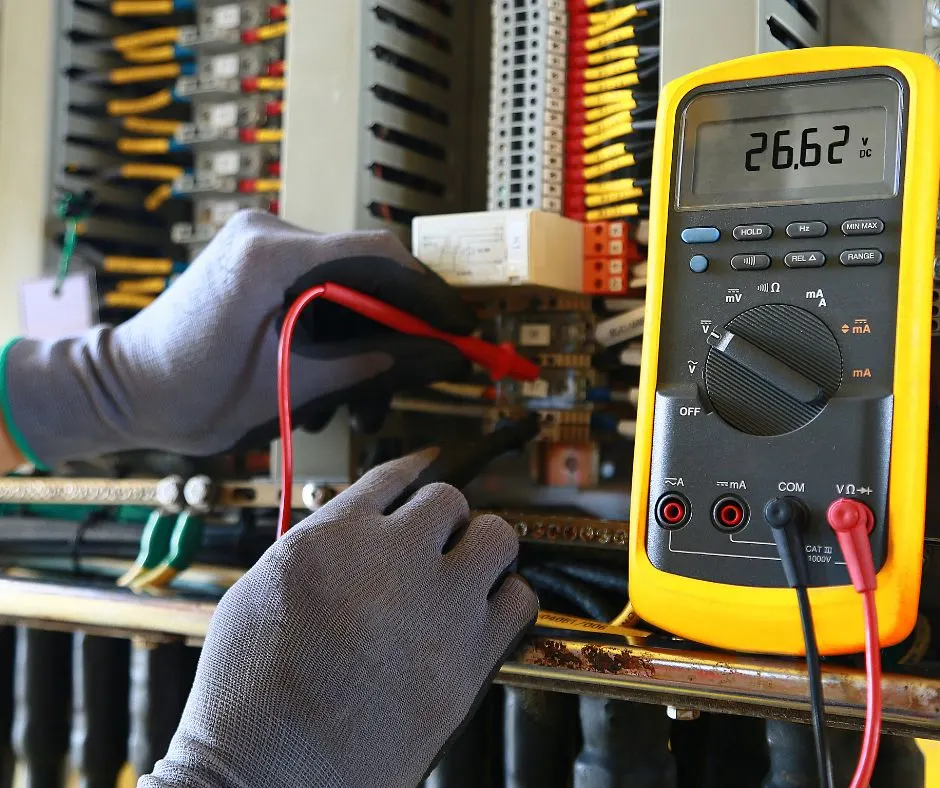

- Verification: Test the system to ensure it’s truly de-energized and safe to work on.

- Completion: When work is done, remove the lockout and tagout devices, re-energize equipment, and notify everyone that it’s safe.

Common Mistakes Contractors Make with LOTO

LOTO is effective when it’s done right, but mistakes can undermine its effectiveness. Some of the most common errors include:

- Skipping the Verification Step: Always verify that equipment is de-energized before beginning work. Never assume that a lock or tag guarantees safety without testing.

- Inadequate Training: Make sure your crew understands LOTO procedures and the risks involved.

- Using Improper Tags or Locks: Invest in high-quality locks and tags that are resistant to tampering or accidental removal.

The Role of LOTO in Compliance and Liability

OSHA requires that employers follow LOTO procedures to protect workers from hazardous energy. Failure to comply can lead to serious consequences, including hefty fines, lawsuits, or even criminal liability in the event of an accident.

LOTO isn’t just about following rules—it’s about actively reducing risk and demonstrating a commitment to safety. By making LOTO a priority on your projects, you’re protecting both your crew and your company.

Why Contractors Need LOTO Training

Your crew can’t follow LOTO procedures if they don’t fully understand them. Providing LOTO training is essential to make sure every team member knows how to properly lock out equipment, identify energy sources, and follow safety protocols. Proper training also helps reinforce the importance of taking safety steps seriously, even when they seem like “extra” work.

At Shaw Consulting Services, LLC, we offer comprehensive LOTO training to help contractors understand and implement these procedures effectively, reducing the risk of costly and dangerous errors.

Tips for Effective LOTO Implementation on Your Projects

Here are some quick tips for integrating LOTO into your projects:

- Designate a LOTO Supervisor: Having a supervisor in charge of LOTO procedures ensures consistency and thoroughness.

- Use High-Quality Lockout Devices: Invest in reliable locks and tags that aren’t easy to tamper with.

- Communicate Clearly: Make sure everyone on-site knows when equipment is locked out and what’s off-limits.

- Conduct Regular Audits: Periodically review LOTO practices to ensure they’re followed correctly and look for areas of improvement.

Working with Shaw Consulting Services, LLC for LOTO Compliance

At Shaw Consulting Services, LLC, we’re dedicated to helping contractors understand and implement LOTO procedures. We provide training, support, and guidance to make sure your team is fully prepared and compliant. Whether it’s for a one-time project or a long-term safety program, we’re here to help.

Final Thoughts

Lockout/Tagout procedures are a fundamental part of electrical safety, and every contractor should take them seriously. By implementing LOTO, you’re not only meeting regulatory standards but also protecting your team from preventable accidents. At Shaw Consulting Services, LLC, we’re ready to support you with LOTO training and consultation to keep your projects safe and compliant.