Energy costs are rising, and facility managers are feeling the pressure. Between utility bills, demand charges, and unexpected spikes, it’s harder than ever to manage energy efficiently, especially in large industrial or commercial facilities where usage varies from hour to hour.

If you’re in charge of operations, maintenance, or sustainability planning, chances are you’ve heard about smart metering. Maybe your utility company mentioned it, or you’ve seen it pop up in industry reports. But what does it mean for your building or plant? And more importantly, how does it help you cut costs, improve performance, and make better decisions?

In this blog, we’ll break down what smart metering really is, how it works in an industrial setting, and how it’s changing the way energy management is done. As a provider of electrical engineering solutions here at Shaw Consulting Services, we’ve seen firsthand how this technology is helping our clients take back control of their energy use—one data point at a time.

What Is Smart Metering?

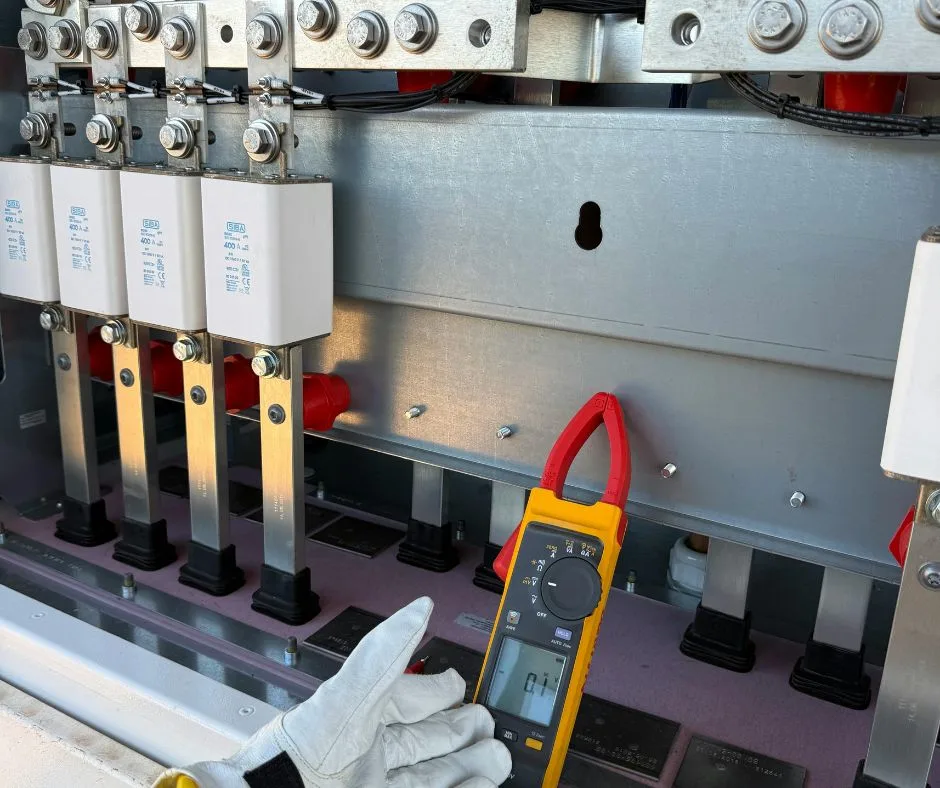

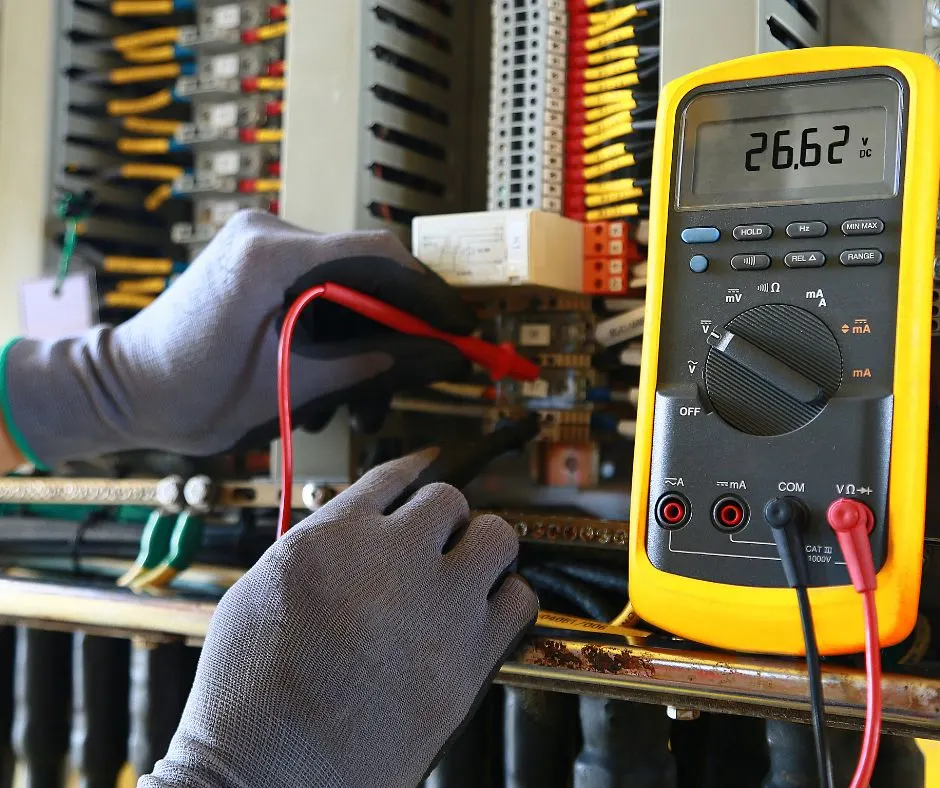

Smart meters are advanced devices that record energy consumption in real-time or at set intervals. Unlike traditional meters that just log usage once a month, smart meters offer a live, ongoing view into how and when your facility is using power.

These meters are often connected to a cloud-based platform or local energy management system that stores and analyzes the data. This allows you to track energy use by zone, machine, or even time of day. And with data that updates every few minutes or seconds, you can spot trends, catch anomalies, and make changes before costs spiral out of control.

Think of it like upgrading from a monthly utility bill to a full dashboard of your energy behavior. You’re no longer flying blind, you’re making informed decisions backed by accurate, real-time insight.

Why This Matters for Industrial Facilities

If you manage an industrial site, your energy load probably fluctuates throughout the day. Heavy machinery, HVAC systems, lighting, and compressed air systems all create peaks and valleys in consumption. Traditional meters just give you a total number at the end of the billing period, without showing how you got there.

That’s where smart metering makes a difference. It shows you:

- When your peak demand occurs

- Which equipment uses the most energy

- Where you might be wasting power

- How operational changes affect your energy profile

In our work at Shaw Consulting Services, we’ve helped manufacturers, warehouses, and processing facilities in the Atlanta region implement smart metering to get ahead of their energy challenges. The results? Lower costs, improved equipment scheduling, and better load balancing.

The Real Benefits of Smart Metering

Here’s how smart metering is transforming energy management for industrial clients:

- Lower Utility Bills: Track and reduce peak demand to avoid costly charges.

- Improved Equipment Scheduling: Shift heavy loads to off-peak hours to save money.

- Faster Problem Detection: Spot unusual spikes in energy use that could signal faulty equipment.

- Regulatory Compliance: Stay ahead of reporting requirements for energy efficiency or sustainability goals.

- Data-Driven Upgrades: Use actual performance data to justify new equipment or retrofits.

Smart meters provide actionable information, not just numbers. This allows teams to respond quickly and improve operations without guessing.

Why Atlanta Facilities Are Paying Attention

In the Atlanta area, where high summer temperatures push HVAC systems into overdrive, energy usage can skyrocket. For facilities operating 24/7, that means real costs and real consequences if demand goes unchecked.

Smart metering gives facility managers in our region a leg up. By understanding when and how energy is being used, teams can take steps to avoid peak charges, spot inefficiencies, and improve overall system health. And since many utilities now offer demand response programs or tiered pricing, having smart meters in place helps you take full advantage.

Who Should Consider Smart Metering?

This technology is a smart move for anyone managing:

- Large commercial buildings or campuses

- Manufacturing plants and distribution centers

- Data centers or high-load facilities

- Buildings preparing for energy audits or LEED certification

If your facility uses significant power or is under pressure to reduce costs, smart metering can provide immediate value. It’s also a great foundation for future energy-saving projects like solar integration, backup systems, or advanced automation.

At Shaw Consulting Services, we’ve found that combining smart metering with Power Studies or Infrared Inspections gives our clients a 360-degree view of energy and equipment performance.

A More Predictable, Efficient Future

When energy usage is visible and predictable, everything else gets easier. Planning budgets. Scheduling production. Meeting sustainability goals. Making equipment decisions.

Smart metering is more than a technology—it’s a tool for changing how your facility thinks about energy. It gives your team the visibility and control needed to turn a line-item expense into a manageable, trackable performance metric.

And while the technology might sound complex, its value is simple. The more you know about your energy use, the more you can do to control it.

Turning Energy Insight into Action

Smart metering is helping industrial facilities take control of their energy use, reduce costs, and make better operational decisions. If your current energy reports leave you with more questions than answers, it may be time to explore smarter solutions.

At Shaw Consulting Services, we help our clients integrate smart energy systems into their broader maintenance and engineering strategies. Whether you’re just getting started or looking to optimize your existing setup, we’re here to support your goals with practical, data-driven insight.