If you’re responsible for electrical safety in an industrial facility, you’ve probably heard of NFPA 70e. But do you understand how critical it is to protect your team and keep your operations compliant? NFPA 70e is more than just a set of guidelines—it’s a crucial tool for keeping workers safe from electrical hazards. And when it comes to training your crew, knowing these standards inside and out can make all the difference.

In this post, we’ll break down what NFPA 70e training is all about, why it’s so important, and how it helps prevent serious accidents on the job. Whether you’re a safety manager or a plant supervisor, this guide will help you understand how to keep your team safe and your facility compliant.

What is NFPA 70e?

Let’s start with the basics. NFPA 70e is the standard for electrical safety in the workplace, published by the National Fire Protection Association (NFPA). Its main goal is to protect workers from the dangers of electrical shock, arc flashes, and other electrical hazards.

The standard outlines the necessary safety procedures for working with or near live electrical equipment, including the use of personal protective equipment (PPE), proper labeling, and the boundaries workers should maintain to stay safe.

Why NFPA 70e Training Matters

Electrical work isn’t just dangerous—it’s potentially fatal. According to OSHA, hundreds of workers are killed or seriously injured every year due to electrical hazards. NFPA 70e training is designed to teach workers how to identify and avoid those risks, so they can perform their jobs safely and confidently.

Without proper training, workers might not recognize the warning signs of a hazardous situation. Or worse, they may engage in unsafe practices that put themselves and others in danger. NFPA 70e training gives them the tools and knowledge to stay safe, no matter what kind of electrical equipment they’re working with.

The Core Components of NFPA 70e Training

So, what exactly does NFPA 70e training cover? Here are the key topics that workers and supervisors learn during the course:

- Electrical Hazard Awareness: Identifying risks like arc flashes, electrical shock, and overloading systems.

- Establishing Safe Work Boundaries: Understanding how to define approach boundaries and how to work within them.

- Proper Use of PPE: Learning how to select and use the right personal protective equipment to prevent injury.

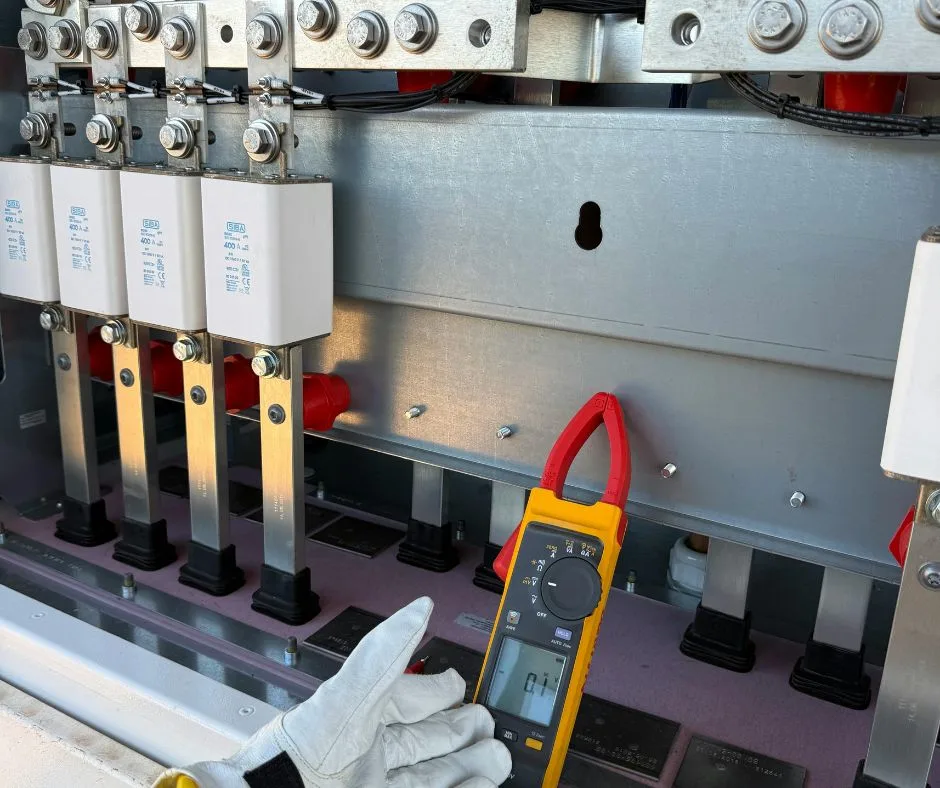

- Arc Flash Risk Assessments: Understanding how to perform or interpret an arc flash study, and what the results mean for safety.

- Lockout/Tagout (LOTO): Ensuring equipment is properly de-energized before any maintenance or repair work begins.

- Safe Work Practices: Following the procedures for safely working on or around live electrical systems, including de-energizing systems when possible.

The training isn’t just about understanding the rules—it’s about making safety a part of your team’s everyday routine.

Who Needs NFPA 70e Training?

In an industrial setting, just about anyone who works around electrical equipment needs NFPA 70e training. This includes electricians, maintenance workers, machine operators, and even supervisors who oversee electrical work. If your team interacts with electrical systems in any way, they need to be trained.

That said, training isn’t a one-size-fits-all approach. The training content is tailored to different levels of responsibility. For example, electricians who directly handle electrical systems will receive more detailed technical training, while maintenance staff might focus more on general electrical safety practices.

Arc Flash Hazards and the Role of NFPA 70e Training

One of the biggest risks in any electrical environment is an arc flash. When an arc flash occurs, it releases an immense amount of energy, often resulting in severe burns, hearing damage, or even death. Arc flashes can also cause equipment damage and fires.

NFPA 70e training helps workers understand what causes an arc flash, how to prevent one, and how to stay safe if they’re ever in the vicinity of a potential flash. It also covers how to read arc flash labels on equipment, so workers know exactly what kind of risk they’re dealing with and what level of PPE they need to wear.

How NFPA 70e Training Keeps Your Facility Compliant

Compliance is a huge factor when it comes to electrical safety. OSHA mandates that employers protect workers from electrical hazards, and NFPA 70e provides the specific guidelines to meet those requirements. Without proper training, your facility could face fines, penalties, or even lawsuits in the event of an accident.

When your team is trained and following NFPA 70e standards, you’re not just protecting them—you’re also ensuring your business stays in compliance with safety regulations. This can help you avoid legal and financial headaches down the line.

Personal Protective Equipment (PPE) and NFPA 70e

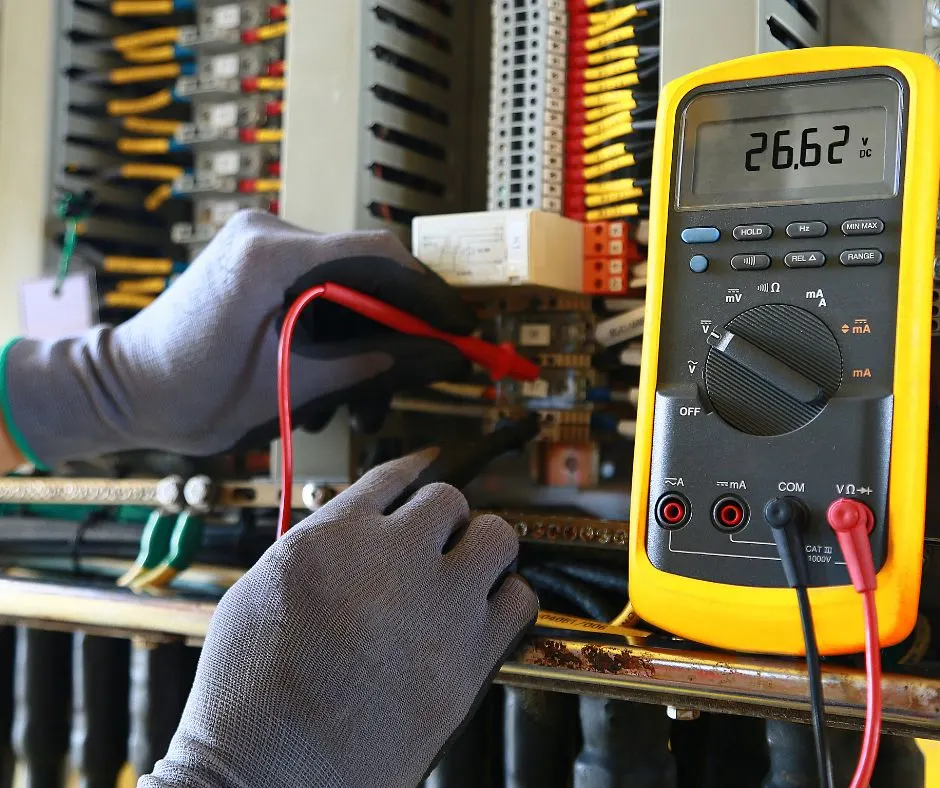

One of the core components of NFPA 70e training is the correct use of personal protective equipment (PPE). Workers need to understand how to choose the right PPE for the job, whether that’s insulated gloves, flame-resistant clothing, or face shields.

PPE is often the last line of defense in the event of an arc flash or electrical shock. When used properly, it can mean the difference between life and death. NFPA 70e training ensures that workers know what to wear and when to wear it, based on the risk level of the task at hand.

Lockout/Tagout (LOTO) and Electrical Safety

Another essential part of NFPA 70e training is understanding lockout/tagout (LOTO) procedures. LOTO ensures that electrical equipment is completely de-energized before any maintenance work begins. This prevents the equipment from being accidentally powered on while workers are still making repairs or adjustments.

Without LOTO, workers are at a much higher risk of electrocution. NFPA 70e training teaches your team how to properly follow these procedures, giving them peace of mind while they’re on the job.

The Role of Power System Studies in NFPA 70e

In addition to training, conducting power system studies is another key aspect of maintaining a safe electrical environment. Power system studies, like arc flash assessments, help you understand where the electrical hazards are in your facility, and they inform the safety practices that NFPA 70e promotes.

At Shaw Consulting Services, LLC, we often perform power system studies to help facilities identify their specific risks and develop tailored safety protocols. By combining these studies with NFPA 70e training, you’re ensuring your team has both the knowledge and the tools to stay safe.

Why Ongoing Training is Essential

Electrical safety isn’t something you can learn once and forget. Systems change, equipment gets upgraded, and safety standards are updated over time. That’s why NFPA 70e requires ongoing training, typically every three years or when there are significant changes in the workplace.

This helps keep your team informed of the latest safety practices and ensures they’re always prepared to handle new challenges. Regular training is a small investment that pays off in the form of fewer accidents and a safer work environment.

How Shaw Consulting Services, LLC Can Help

At Shaw Consulting Services, LLC, we take electrical safety seriously. We offer NFPA 70e training tailored to your facility’s needs, ensuring your team understands how to stay safe and compliant. Our expert trainers break down complex concepts into simple, actionable steps that your crew can implement immediately.

Whether you need a refresher course or full-scale training for your entire team, we’re here to help you keep your workplace safe and your workers protected.

The Importance of Investing in Safety

When it comes to electrical safety, there’s no room for cutting corners. NFPA 70e training is an essential part of keeping your team safe from the dangers of electrical hazards. By investing in regular training, you’re not only protecting your employees but also ensuring that your facility remains compliant with regulations.

Shaw Consulting Services, LLC is ready to help you implement a strong NFPA 70e program and provide your team with the training they need to stay safe on the job.