Running a business means juggling countless responsibilities, but your electrical system probably isn’t something you think about daily—until something goes wrong. The thing is, electrical issues rarely announce themselves with flashing lights or loud noises. Instead, they build quietly over time, often showing subtle warning signs that many people miss.

That’s where infrared electrical inspections come in. They’re designed to uncover hidden problems before they spiral into costly repairs or dangerous breakdowns. In this blog, we’ll explore five key signs that your business might need an infrared inspection—and how addressing these issues now can save you time, money, and a whole lot of stress.

What Is an Infrared Electrical Inspection?

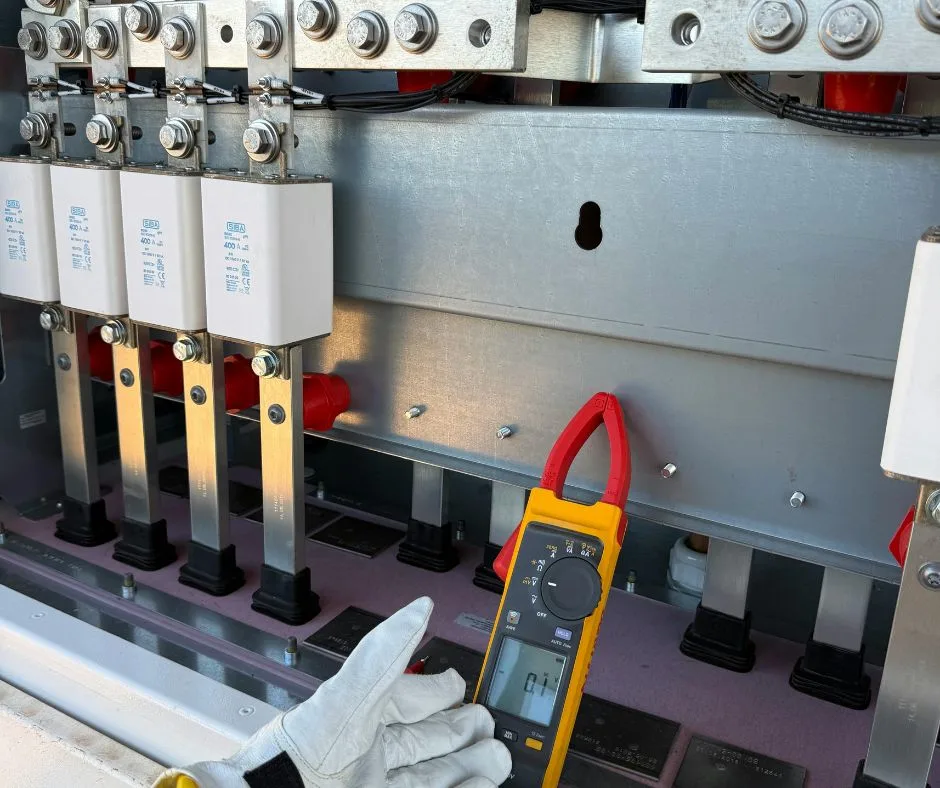

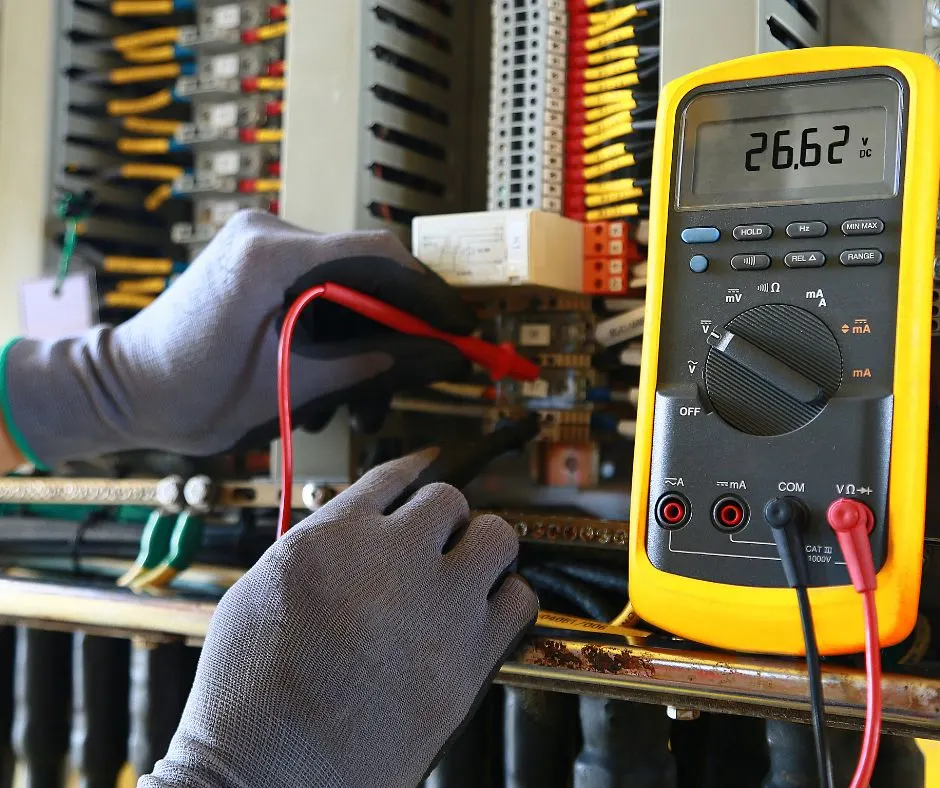

An infrared electrical inspection uses advanced technology to detect heat in your electrical system. Heat buildup is often the first sign of trouble, like loose connections, overloaded circuits, or failing components. Infrared thermography (or thermographic scanning) allows professionals to spot these problems early—before they escalate into downtime, damaged equipment, or even fires.

The process is non-invasive and doesn’t disrupt your operations. A technician uses an infrared camera to scan your electrical panels, switchgear, and other components. The camera identifies temperature variations, which are then analyzed to determine whether there’s an issue.

Sign #1: Frequent Equipment Failures

Do you find yourself constantly dealing with broken-down equipment? It’s not always the machine’s fault. Electrical systems can overheat due to loose connections or worn-out components, causing equipment to malfunction.

An infrared inspection identifies these “hot spots,” giving you the chance to fix the underlying issue before it takes another piece of equipment offline. For businesses that rely heavily on machinery, this can be a game-changer.

Sign #2: Increasing Energy Bills

If your energy bills seem to keep climbing without a clear explanation, it could be a sign of trouble lurking in your electrical system. Faulty or deteriorating electrical components can cause energy to be wasted—kind of like a slow leak in a water pipe.

Infrared inspections pinpoint inefficiencies like overheated circuits, enabling you to address them and improve your facility’s energy efficiency. Over time, this can lead to significant cost savings.

Sign #3: Circuit Breakers Tripping Often

A tripped breaker might seem like a minor inconvenience, but if it’s happening frequently, it’s a red flag. Overloaded circuits, faulty wiring, or damaged equipment could be the cause. The problem? You can’t always see the issue just by opening the panel.

An infrared scan reveals where circuits are under strain, so you can address the problem before it leads to more serious failures—or worse, an electrical fire.

Sign #4: Unusual Heat or Smell Around Electrical Panels

Have you ever noticed a strange warmth or smell near your electrical equipment? That’s often a sign of overheating, which can happen when connections are loose or wiring is damaged. Ignoring these signs can lead to a full-blown electrical outage—or even a fire.

Infrared electrical inspections are designed to catch these issues early, giving you peace of mind that your facility is operating safely.

Sign #5: Aging Electrical Systems

If your business operates in an older building or uses aging equipment, you’re at a higher risk for electrical problems. Over time, components wear down, connections loosen, and systems become less efficient.

Infrared inspections are particularly useful for extending the life of older systems. By catching issues early, you can make targeted repairs instead of dealing with expensive replacements or unplanned downtime.

The Benefits of Regular Infrared Inspections

So, why bother with these inspections in the first place? Here are a few key benefits:

- Save Money: Preventive maintenance is always cheaper than emergency repairs.

- Ensure Safety: Overheated electrical components are one of the leading causes of fires.

- Stay Compliant: If your facility follows NFPA 70E guidelines, regular inspections can help ensure compliance.

How Infrared Inspections Work: Step-by-Step

- Preparation: The technician ensures that all panels and equipment are safely accessible.

- Scanning: Using an infrared camera, they scan electrical systems for heat anomalies.

- Analysis: The data is reviewed to identify potential issues.

- Report: A detailed report outlines the findings and recommends action.

The whole process is quick, non-invasive, and doesn’t interrupt your operations.

How Shaw Consulting Services, LLC Can Help

At Shaw Consulting Services, LLC, we’ve helped businesses across Atlanta stay ahead of electrical problems with expert infrared inspections. Our team combines advanced technology with years of experience to ensure your facility runs smoothly and safely. We don’t just point out problems—we work with you to find practical solutions that fit your needs.

When to Schedule Your Next Inspection

Wondering how often you should get an infrared electrical inspection? For most businesses, an annual inspection is ideal. However, if your facility has older equipment, operates in extreme conditions, or has experienced frequent issues, more frequent inspections may be necessary.

Remember: Electrical problems don’t always announce themselves with a bang. Often, they start with subtle signs—like increasing energy bills or a warm electrical panel. Catching these issues early with an infrared electrical inspection can save you money, keep your business running smoothly, and even prevent dangerous situations.

If you’re ready to take a proactive approach to your electrical system, reach out to Shaw Consulting Services, LLC. We’re here to help you spot the problems before they become crises.