If you’re managing a facility, you know that keeping energy costs in check is crucial. But should you rely on electrical metering, traditional monitoring, or both? The right choice depends on your facility’s needs.

In this blog, we’ll explore the differences between electrical metering and traditional monitoring to help you determine the best approach for improving efficiency and reducing costs.

What is Electrical Metering?

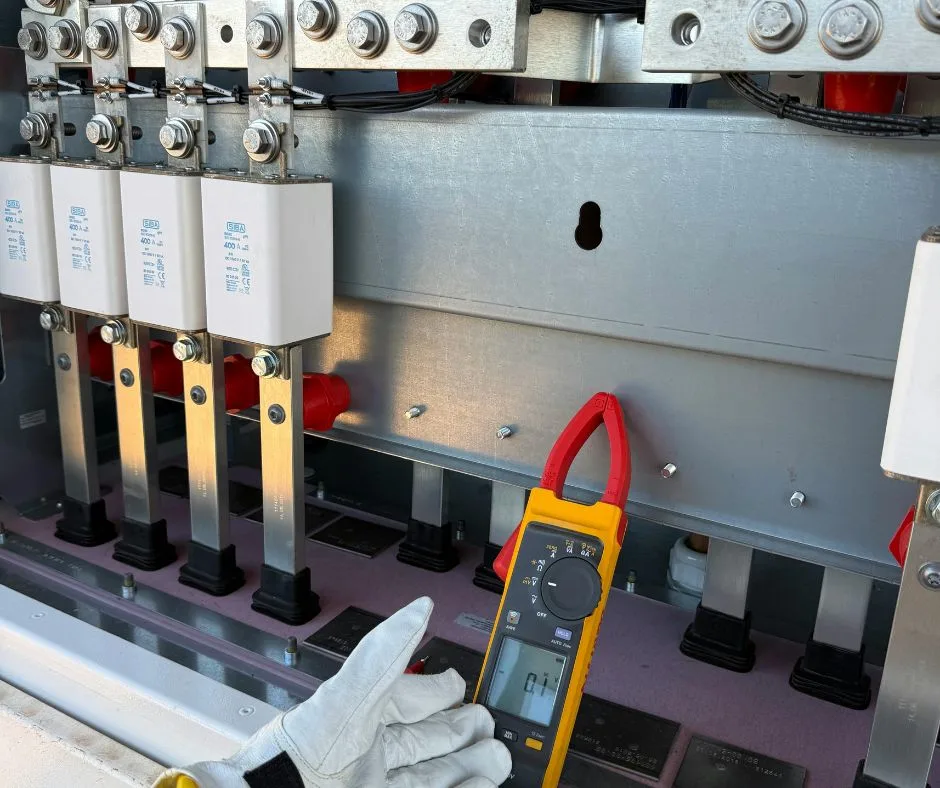

Electrical metering is a process used to measure and monitor energy consumption in real time. It provides critical insights into how electricity is being distributed and used within a facility. By collecting precise data on power usage, electrical meters help businesses optimize energy efficiency, reduce operational costs, and maintain system reliability.

There are different types of electrical meters, including:

- Smart Meters: These meters provide real-time data and allow for remote monitoring and control of energy consumption.

- Submeters: Used in large facilities, submeters track energy usage for specific departments, tenants, or equipment, helping pinpoint areas of high consumption.

- Power Quality Meters: These meters analyze voltage fluctuations, harmonic distortions, and power factor, helping detect potential inefficiencies and electrical issues before they escalate.

Electrical metering plays a crucial role in modern energy management strategies. With the integration of digital and IoT-enabled meters, businesses can leverage automated data collection and advanced analytics to make informed decisions that enhance system performance and sustainability.

Shaw Consulting Services, LLC provides customized electrical metering solutions that align with industry best practices and compliance standards. Electrical metering measures real-time energy consumption and provides detailed data on how electricity is being used. This information helps businesses:

- Identify energy waste and optimize consumption

- Improve system efficiency and reduce costs

- Prevent overloading and electrical failures

What is Traditional Monitoring?

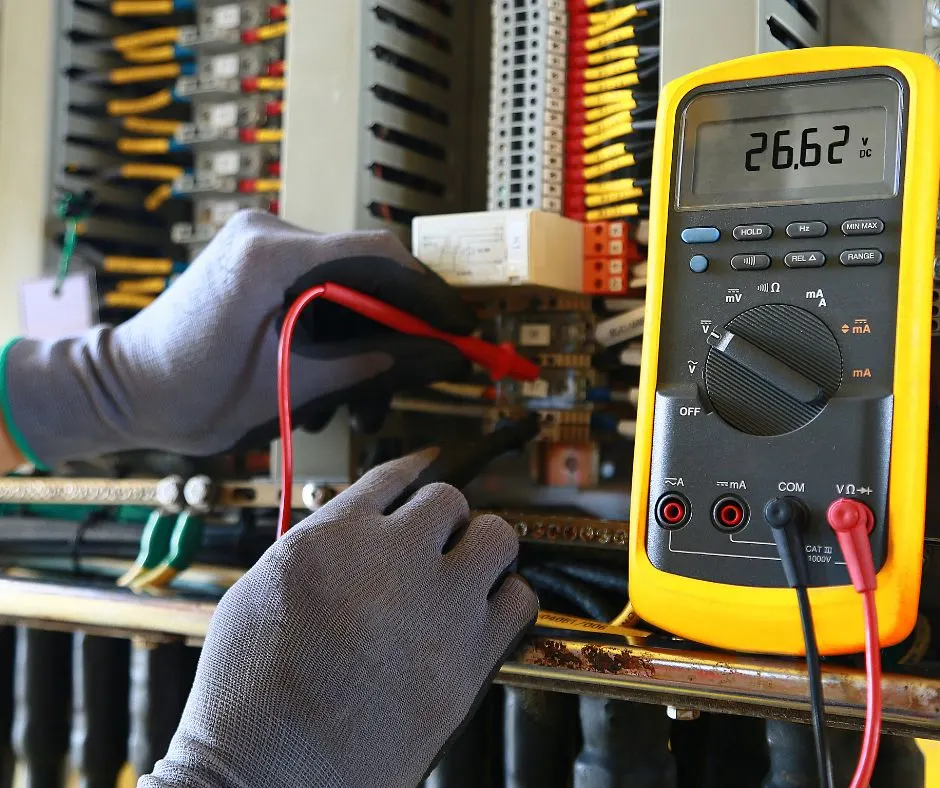

Traditional monitoring refers to the process of tracking electrical system performance over time without real-time data collection. It involves periodic inspections, manual readings, and historical trend analysis to assess system reliability and efficiency. Unlike modern electrical metering, traditional monitoring relies on scheduled evaluations and does not provide immediate feedback on system anomalies.

Facilities using traditional monitoring may implement strategies such as monthly or quarterly power audits, manual logging of energy consumption, and reviewing historical reports to identify inefficiencies. While this method is useful for long-term planning and trend detection, it cannot address immediate issues that may arise within an electrical system.

By incorporating traditional monitoring alongside advanced metering solutions, businesses can enhance their understanding of both real-time performance and long-term trends, ensuring more comprehensive energy management and system optimization. Traditional monitoring tracks electrical performance over time, offering insights into long-term trends. It helps facilities:

- Detect patterns of inefficiency

- Predict potential failures before they happen

- Maintain compliance with safety standards

Key Differences Between Electrical Metering and Traditional Monitoring

|

Feature |

Electrical Metering |

Traditional Monitoring |

|

Real-Time Data |

Yes |

No |

|

Long-Term Analysis |

Limited |

Yes |

|

Fault Detection |

Immediate |

Trend-Based |

|

Energy Efficiency Insights |

High |

Moderate |

|

Best For |

Reducing costs and optimizing usage |

Predicting long-term reliability issues |

Which One is Right for Your Facility?

- Use electrical metering if you need real-time data on energy use to optimize efficiency and reduce costs.

- Use traditional monitoring if you want long-term insights into performance trends and potential failures.

- Combine both for the most comprehensive approach to facility management.

Benefits of Combining Electrical Metering and Monitoring

Integrating electrical metering and traditional monitoring systems provides a comprehensive approach to energy management and electrical system optimization. Here’s how combining both systems benefits modern facilities:

- Maximizing Energy Efficiency – By leveraging real-time data from electrical metering and long-term insights from traditional monitoring, businesses can identify patterns of energy waste and optimize their usage.

- Enhancing System Stability – Electrical metering provides immediate feedback on system performance, while monitoring identifies historical trends, allowing facilities to proactively address inefficiencies and enhance reliability.

- Reducing Maintenance Costs – Combining these systems helps detect faults early, preventing expensive repairs and minimizing downtime.

- Improving Safety and Compliance – Facilities can ensure compliance with NFPA 70E safety regulations by monitoring real-time energy consumption and historical system performance to mitigate electrical hazards.

- Better Load Management – Understanding both real-time and long-term load trends helps distribute energy usage more effectively, preventing overloads and balancing demand.

- Enhancing Predictive Maintenance – Metering provides immediate alerts for unusual activity, while monitoring helps predict equipment failure trends, enabling proactive maintenance strategies.

- Reducing Carbon Footprint – Optimizing energy consumption through combined systems supports sustainability goals and reduces overall environmental impact.

By integrating electrical metering and monitoring, businesses can achieve a smarter, more responsive energy strategy that drives efficiency, reliability, and long-term cost savings. Shaw Consulting Services, LLC helps businesses design and implement these integrated solutions to keep operations running smoothly and efficiently. By integrating both systems, facilities can:

- Maximize energy efficiency while maintaining long-term system stability

- Detect and address electrical faults before they lead to equipment failure

- Improve overall facility performance and reduce maintenance costs

At Shaw Consulting Services, LLC, we help businesses find the best solutions for their specific needs. Whether it’s electrical metering, traditional monitoring, or a hybrid approach, we ensure your facility operates efficiently.

Choosing between electrical metering and traditional monitoring depends on your facility’s goals. By understanding the benefits of each, you can make informed decisions that improve energy efficiency and system reliability. If you’re unsure where to start, Shaw Consulting Services, LLC is here to help you optimize your electrical systems for long-term success.