The True Value Of Infrared Thermal Imaging For Businesses Large And Small

As experts in electrical engineering and safety training, we are dedicated to ensuring the reliability and safety of your electrical systems. One of the most effective tools we use is infrared thermal imaging, which plays a crucial role in preventing electrical failures.

What Is Infrared Thermal Imaging?

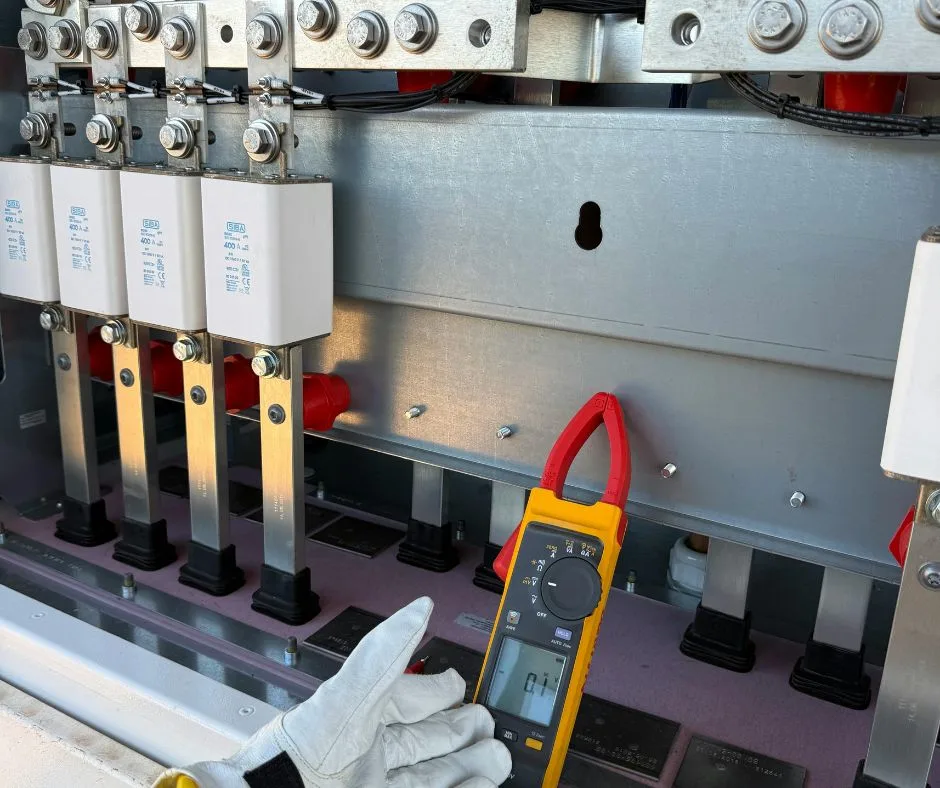

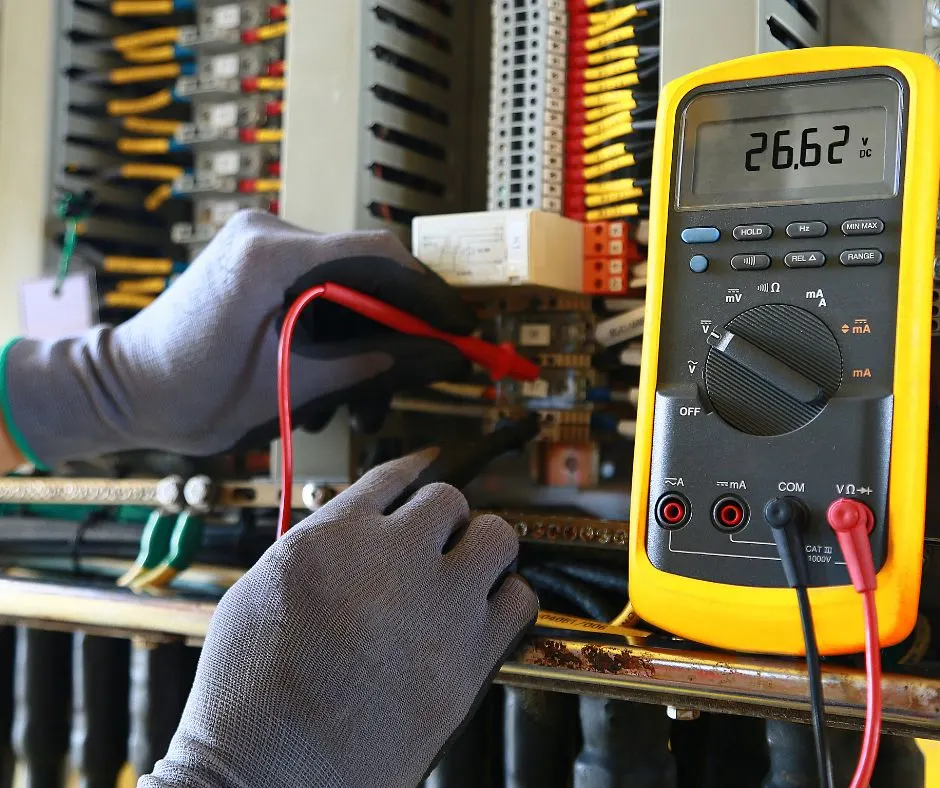

Infrared thermal imaging involves using thermal cameras to detect heat patterns within electrical systems. By visualizing temperature variations, this technology allows us to identify hot spots that could indicate potential issues such as overloaded circuits, loose connections, or failing components. This proactive approach enables us to address problems before they escalate into costly and dangerous failures.

Some Important Benefits of Leveraging Infrared Thermal Imaging

- Early Detection of Issues: Infrared thermal imaging allows us to detect problems at an early stage, significantly reducing the risk of electrical failures. By identifying and addressing these issues promptly, we can prevent unexpected breakdowns and costly downtime.

- Non-Invasive Inspections: Unlike traditional methods, infrared thermal imaging is non-invasive and can be conducted without disrupting your operations. This means that we can perform inspections without the need for shutdowns or interruptions, ensuring that your business continues to run smoothly.

- Cost-Effective Maintenance: Regular infrared thermal imaging inspections help to reduce maintenance costs by preventing unexpected failures. By identifying potential problems early on, we can implement targeted maintenance strategies that minimize the need for expensive repairs or replacements.

- Enhanced Safety: Safety is our top priority, and infrared thermal imaging plays a vital role in ensuring the safety of your electrical systems. By detecting hot spots and potential fire hazards, we can take immediate action to mitigate risks and protect your employees, equipment, and facilities.

- Energy Efficiency: Infrared thermal imaging can also help improve energy efficiency by identifying areas where energy is being wasted. By addressing these inefficiencies, we can help you optimize your energy consumption, reduce costs, and contribute to a more sustainable operation.

Applications in Electrical Systems

Infrared thermal imaging can be applied to various aspects of electrical systems, including:

- Preventive Maintenance: Regular inspections of electrical systems using infrared thermal imaging can help identify and address potential issues before they lead to failures. This proactive approach ensures the reliability and longevity of your equipment.

- Safety Compliance: Infrared thermal imaging helps you meet safety regulations and standards by ensuring that your electrical systems operate within safe temperature ranges. By complying with these standards, you can avoid penalties and ensure a safe working environment.

- Energy Audits: Infrared thermal imaging is an essential tool for conducting energy audits. By identifying areas of energy loss, such as poorly insulated components or overheating equipment, we can recommend energy-saving measures that improve efficiency and reduce costs.

Case Studies and Examples

Here are a few real-world examples of how Shaw’s infrared thermal imaging has helped our clients:

- Manufacturing Plants: In a manufacturing plant, our infrared thermal imaging inspection revealed overheating machinery components. By addressing the issue promptly, we prevented a potential breakdown that could have resulted in significant production downtime and costly repairs.

- Commercial Buildings: During a routine inspection of electrical panels in a commercial building, we detected a hot spot indicating a loose connection. By tightening the connection, we eliminated the risk of a potential fire hazard and ensured the safety of the building and its occupants.

- Data Centers: In a data center, our infrared thermal imaging identified hotspots in server racks, indicating inadequate cooling. By optimizing the cooling system, we improved the efficiency of the data center, reduced energy consumption, and helped extend the lifespan of the equipment.

At Shaw Consulting Services, we are committed to providing the highest level of service and expertise to ensure the reliability and safety of your electrical systems. Infrared thermal imaging is a powerful tool that allows us to detect and address potential issues before they become critical. By incorporating this technology into your maintenance routine, you can save time, money, and lives by preventing electrical failures. Contact us today to learn more about how our infrared thermal imaging services can benefit your business.