If you’re running an industrial facility, keeping your team safe from electrical hazards is always a top priority. Among those hazards, arc flashes are one of the most dangerous, and they can happen in a split second. The energy released during an arc flash can cause severe burns, hearing loss, blindness, or even death. The reality is, that you can’t afford to take chances when it comes to your workers’ safety.

That’s where an accurate arc flash assessment comes into play. Whether you’re an industrial plant manager or an electrical safety officer, you need to know how to prevent arc flashes, protect your crew, and comply with regulations. In this post, we’re breaking down why arc flash assessments are critical, how they work, and what benefits they offer your facility.

What is an Arc Flash and Why Is It Dangerous?

An arc flash is an electrical explosion or discharge that results from a short circuit through the air. When a flash occurs, temperatures can soar to over 35,000 degrees Fahrenheit—hotter than the surface of the sun. The heat, light, and force released in that fraction of a second can lead to catastrophic injuries. Workers nearby are at risk for severe burns, hearing damage, eye injuries, and even death.

The potential for harm isn’t just limited to electricians working on the equipment. Arc flashes can also harm anyone standing nearby, which makes them a major safety issue in industrial environments.

OSHA & NFPA 70e Standards for Arc Flash Assessments

Here’s the thing—protecting your workers isn’t just about doing the right thing. It’s also about staying compliant with safety standards like those outlined by OSHA and the NFPA 70e (National Fire Protection Association). The NFPA 70e sets the guidelines for electrical safety in workplaces, and one of the major components of that is conducting an arc flash risk assessment.

These standards help define the boundaries of where workers are safe, what personal protective equipment (PPE) is needed, and how to reduce the risk of electrical shock or burns.

How Arc Flash Assessments Help Protect Workers

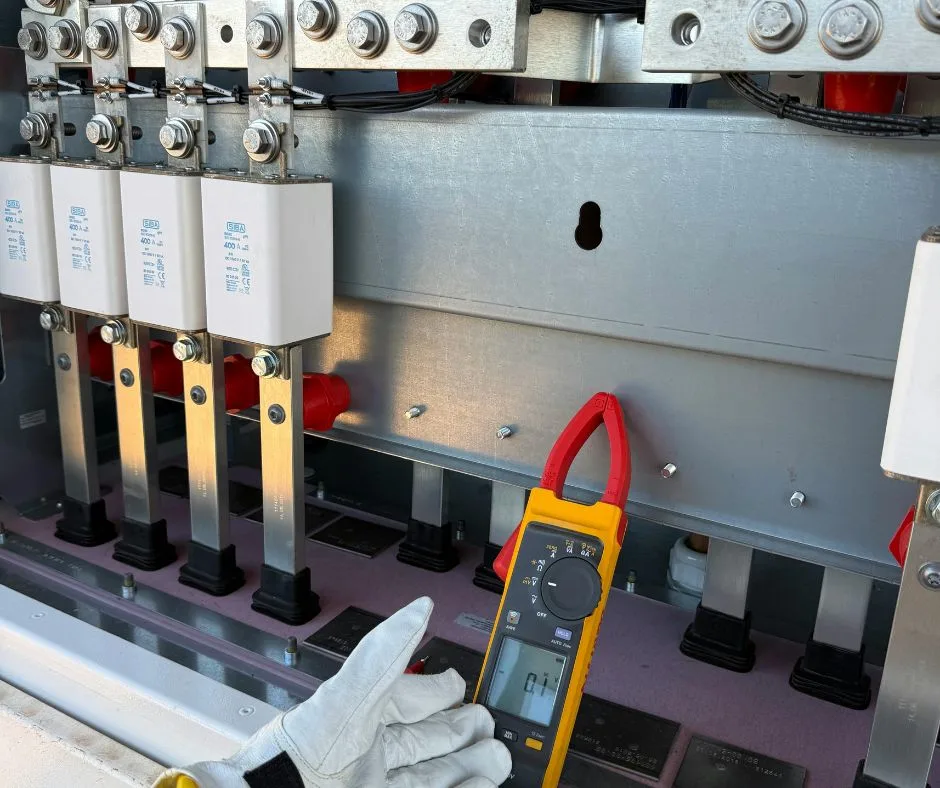

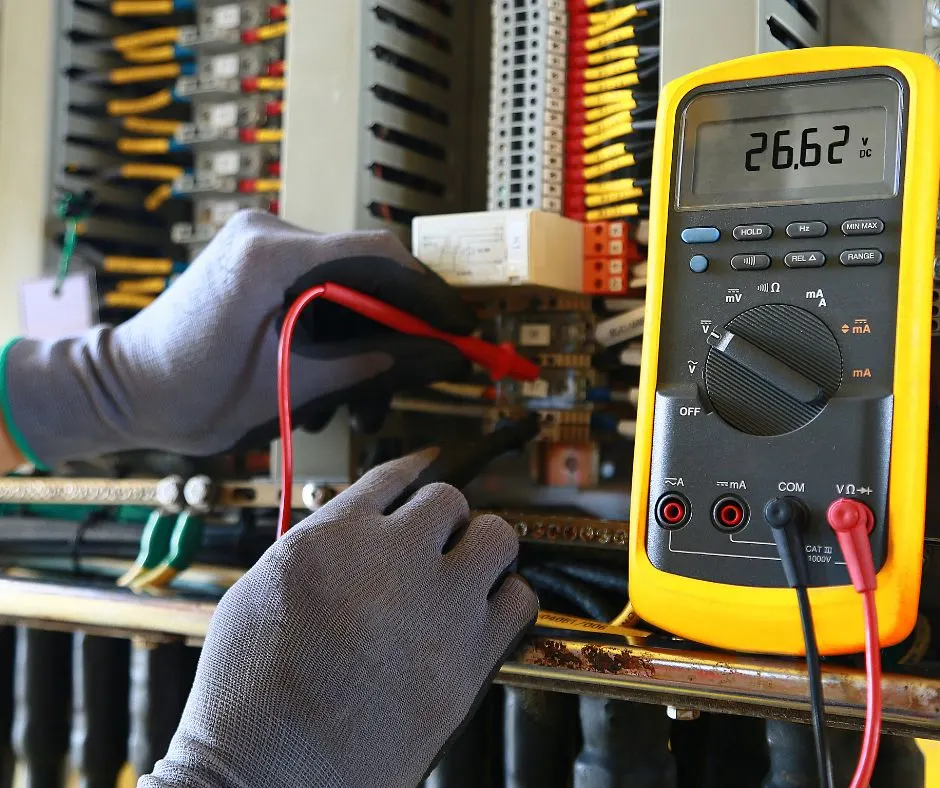

Arc flash assessments are a crucial step in identifying potential hazards. When a professional, like our team at Shaw Consulting Services, LLC, conducts an arc flash assessment, they evaluate your facility’s electrical system, equipment, and work environment. By understanding where the highest risks are, you can reduce the chances of a flash happening—and if it does, the damage can be minimized.

Assessments give you clear data on where electrical risks exist, allowing you to put safety measures in place, such as using the right PPE or ensuring safe working distances. This step alone can save lives.

Arc Flash Labels: A Life-Saving Tool

One often overlooked part of arc flash safety is labeling. Arc flash labels provide critical information about the potential hazard and what protective measures workers should take. This includes details like the arc flash boundary, PPE requirements, and incident energy levels.

Without these labels, workers might unknowingly expose themselves to danger. By making sure every electrical panel and piece of equipment is labelled correctly, you’re helping to create a safer work environment for everyone.

Common Mistakes in Arc Flash Assessments

Even though arc flash assessments are essential, they aren’t always done right. Some of the most common mistakes include not accounting for all electrical factors, like equipment age and condition, or failing to consider how modifications to your electrical system might impact safety. These errors can leave serious gaps in your safety plan.

Another common issue is not updating assessments regularly. Electrical systems change over time, and new equipment or repairs can affect the results of an old assessment. That’s why regular updates are a must.

Benefits of Accurate Arc Flash Assessments for Industrial Facilities

Let’s be real—no one wants to deal with workplace injuries. Beyond the human cost, accidents lead to downtime, reduced productivity, and expensive lawsuits. An accurate arc flash assessment helps mitigate those risks by giving you a clear picture of your electrical hazards. This way, you can implement protective measures before an accident occurs.

On top of that, conducting an assessment can also help you save on insurance costs. Many insurance providers offer lower premiums for businesses that actively work to improve safety, so it’s a win-win.

Impact on Insurance and Liability

Speaking of insurance, did you know that failing to do an arc flash assessment could hurt you financially? In the event of an arc flash incident, not having a proper assessment could increase your liability. You could be held responsible for injuries or damages, which could lead to hefty fines or lawsuits.

Having an accurate assessment in place shows that you’re doing your due diligence to protect your team and comply with regulations. This can significantly reduce your liability if something ever goes wrong.

What to Expect During an Arc Flash Assessment

So, what happens during an arc flash assessment? A consultant will visit your facility and start by collecting data from your electrical system. This includes information about your equipment, electrical loads, and the layout of your system. From there, they’ll run calculations to figure out the arc flash potential for each piece of equipment.

At Shaw Consulting Services, LLC, we use advanced tools and software to ensure our assessments are thorough and accurate. We’ll also provide you with a detailed report that highlights areas of concern and offers actionable recommendations to improve safety.

Working with Engineering Consulting Services for Accurate Assessments

Partnering with experienced consulting services can make all the difference when it comes to arc flash assessments. At Shaw Consulting Services, LLC, we’ve been working with industrial facilities across Atlanta and beyond to ensure they stay safe and compliant.

Instead of leaving assessments to in-house staff who may not have the right expertise, you can rely on professionals to handle the job accurately and efficiently. Our team has the know-how to spot potential hazards and recommend the best solutions for your specific situation.

Why Regular Arc Flash Assessments Are Essential

Electrical systems are dynamic, meaning they change over time. Whether you’ve added new equipment, upgraded old machinery, or just conducted regular maintenance, your electrical landscape may not be the same as it was when you last did an assessment. That’s why it’s important to conduct regular arc flash assessments to stay ahead of potential risks.

Safety standards also change. What was compliant five years ago might not meet today’s guidelines, so staying up to date is key to keeping your team safe and avoiding fines.

Signs It’s Time for a New Arc Flash Assessment

Wondering if it’s time for a new assessment? Look out for these signs:

- You’ve installed new equipment or upgraded existing systems.

- Your facility has undergone renovations or expansions.

- It’s been more than five years since your last assessment.

If any of these apply, it’s probably time to give your system another look.

Partnering with Shaw Consulting Services, LLC for Your Arc Flash Needs

At Shaw Consulting Services, LLC, we’re here to help you make sense of it all. We know that safety is a priority for you, and our team is dedicated to helping you navigate the complexities of arc flash assessments with ease. Our job is to ensure your facility is as safe as possible without disrupting your day-to-day operations.

Whether it’s conducting a new assessment, updating an old one, or offering guidance on NFPA 70e compliance, we’ve got you covered.

Invest in Safety Now, Save Lives Later

At the end of the day, arc flash assessments are an investment in your workers’ safety and your facility’s future. By taking the time to get an accurate assessment done, you’re not only protecting lives but also reducing the chances of downtime, accidents, and liability. Shaw Consulting Services, LLC is here to help you every step of the way, ensuring your industrial facility stays compliant and safe.