When it comes to workplace electrical safety, the adage “an ounce of prevention is worth a pound of cure” couldn’t be more accurate. Yet many facilities approach electrical design and safety protocols as separate concerns, addressing safety issues only after systems are installed. This disconnected approach creates unnecessary risks, drives up costs, and leaves workers vulnerable to electrical hazards that could have been prevented from the start.

The most effective electrical design services don’t just focus on power distribution and equipment specifications. They integrate comprehensive safety protocols directly into the design process, creating facilities where safety is built into every circuit, panel, and conductor. By combining electrical system design with arc flash assessments, NFPA 70E training requirements, and PPE planning, companies can create safer workplaces while ensuring compliance with regulatory standards.

Why Integration Matters: The Real Cost of Disconnected Approaches

Most electrical incidents don’t happen because of equipment failure. They happen because safety wasn’t considered early enough in the design process. When safety protocols are treated as afterthoughts rather than foundational elements, facilities face serious consequences.

Consider what happens when arc flash hazard analysis occurs only after installation is complete. Engineers discover hazards that require expensive retrofits, additional protective equipment, or operational restrictions that impact productivity. Workers face higher incident energy levels than necessary because system configurations weren’t optimized for safety. The facility struggles to develop accurate PPE requirements because the electrical system wasn’t designed with worker protection in mind.

This reactive approach also creates compliance challenges. NFPA 70E and OSHA standards require specific safety measures that are far easier to implement during design than to retrofit later. Facilities that separate design from safety often discover compliance gaps during inspections, resulting in citations, fines, and rushed corrective actions.

The financial impact extends beyond immediate retrofit costs. Electrical incidents result in worker injuries, equipment damage, downtime, insurance claims, and potential legal liability. When facilities in the Atlanta area experience an arc flash incident, the average cost exceeds $1 million when accounting for medical expenses, lost productivity, equipment replacement, and regulatory penalties.

Understanding the Components: What Integration Really Means

Integrating electrical design services with safety protocols means considering worker protection, hazard mitigation, and compliance requirements at every stage of the design process. This integration involves several key components that work together to create comprehensive safety.

Arc Flash Assessment Integration

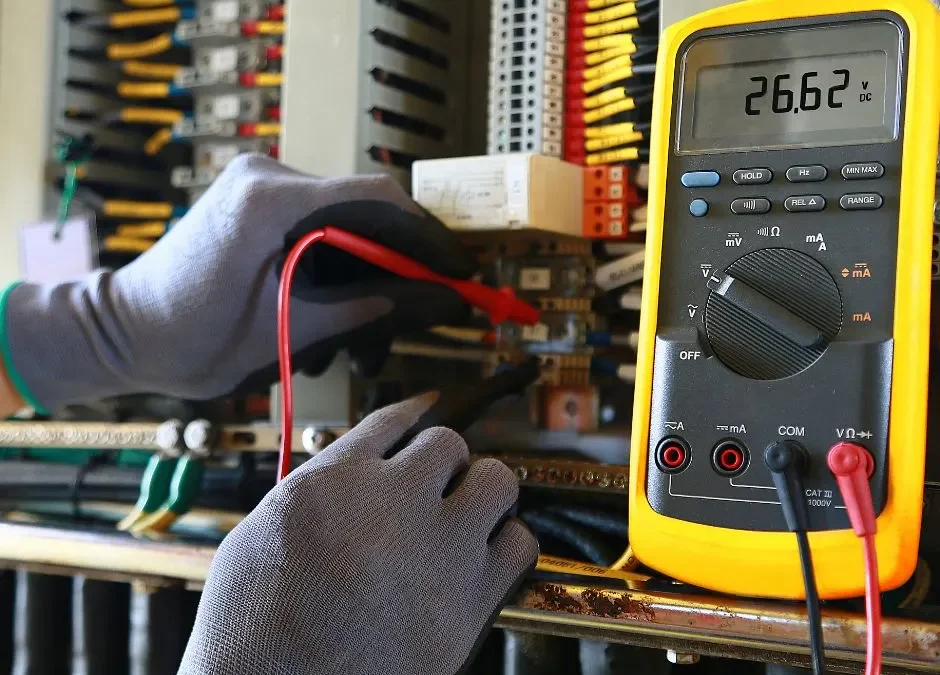

Arc flash assessments identify the thermal and blast hazards workers face when performing tasks on energized equipment. When integrated into electrical design services, these assessments influence system configuration decisions that reduce incident energy levels before installation begins.

Designers can specify equipment with lower arc flash ratings, configure systems to minimize fault current levels, and incorporate features like zone-selective interlocking that reduce clearing times. By running arc flash hazard analysis during design rather than after construction, engineers can make cost-effective decisions that dramatically improve safety outcomes.

For Atlanta facilities, this integrated approach has proven particularly valuable. Manufacturing plants that incorporated arc flash considerations during design phases have achieved incident energy reductions of 40-60% compared to facilities where assessments occurred post-installation.

NFPA 70E Training Alignment

NFPA 70E training prepares workers to recognize electrical hazards and follow safe work practices. When electrical system design incorporates training requirements from the start, facilities create environments where safe practices are easier to follow and maintain.

This means designing systems with clear equipment labeling locations, adequate working spaces that meet approach boundary requirements, and documentation that supports ongoing training programs. Designers who understand NFPA 70E requirements can specify equipment arrangements that facilitate safe maintenance, create electrical rooms with proper clearances, and incorporate features that reduce the need for energized work.

The integration between design and training also ensures that facility-specific procedures match actual system characteristics. When designers provide detailed information about system configurations, fault levels, and clearing times, safety professionals can develop accurate job hazard analyses and work permits that reflect real conditions.

PPE Planning and System Design

Personal protective equipment provides the last line of defense against electrical hazards, but effective protection requires careful planning that begins during design. PPE planning integrated with electrical design services ensures that protection requirements are reasonable, equipment is accessible when needed, and workers understand exactly what protection each task requires.

Designers who consider PPE needs can make decisions that reduce protection requirements, making compliance more practical and cost-effective. Specifying maintenance switches, incorporating remote racking systems, and configuring equipment to enable de-energized work all reduce the PPE burden on workers and maintenance teams.

This integration also addresses storage and accessibility. Electrical rooms designed with adequate space for PPE storage ensure that workers can access protection equipment easily. Documentation that clearly identifies PPE requirements for specific equipment helps workers select appropriate gear without confusion or delay.

The Design Process: Building Safety In From Day One

Creating truly integrated electrical design services requires a systematic approach that considers safety at every decision point. The most successful projects follow a structured process that begins with safety goals and maintains that focus through final commissioning.

Initial Safety Assessment

Before drawing a single line on electrical plans, integrated design begins with understanding facility-specific safety needs. This assessment considers the types of work performed, maintenance requirements, worker skill levels, and existing safety culture.

For industrial facilities, this might involve analyzing equipment that requires frequent maintenance, identifying areas where energized work cannot be avoided, and understanding production schedules that affect maintenance windows. Commercial properties might focus on accessibility for maintenance contractors, coordination with building management systems, and minimizing disruption to occupants.

This assessment phase also establishes clear safety goals. Rather than simply meeting minimum code requirements, facilities should define target incident energy levels, PPE limitations they want to achieve, and specific hazards they want to eliminate through design.

System Configuration for Safety

With safety goals established, designers can develop system configurations that optimize protection. This involves decisions about voltage levels, fault current management, protective device coordination, and equipment selection.

Workplace safety design often benefits from distributed architectures that limit fault current levels in specific areas. Rather than feeding entire facilities from a single service point, designers can create multiple services or transformers that reduce available fault current. This configuration naturally lowers arc flash hazard levels throughout the facility.

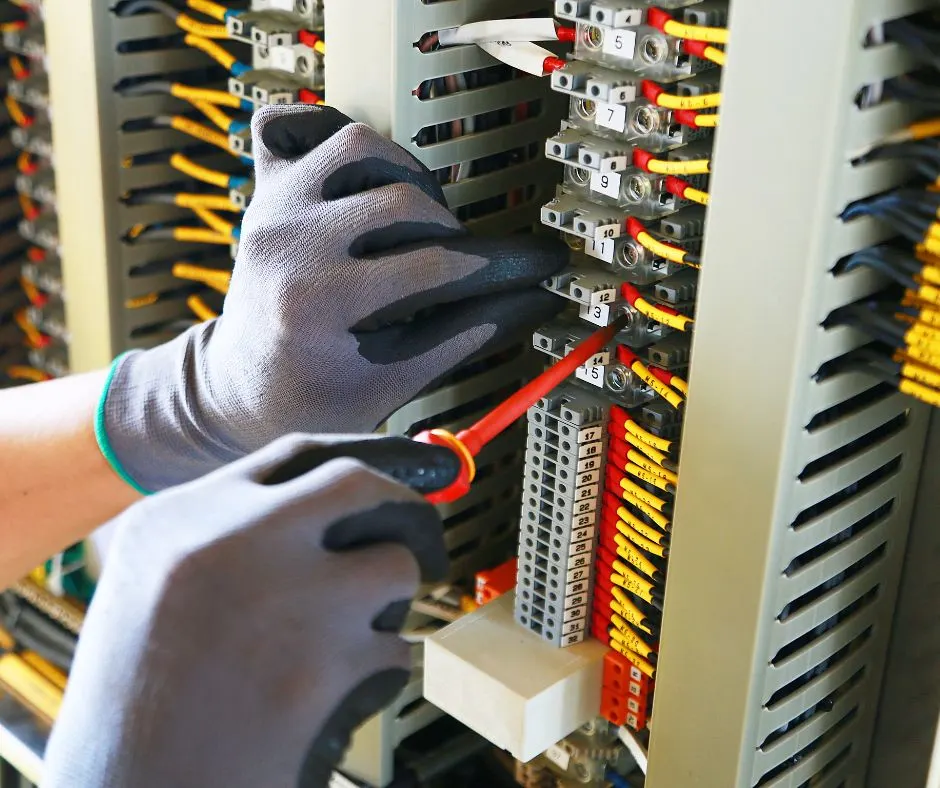

Equipment selection plays an equally important role. Modern switchgear with arc-resistant designs, circuit breakers with faster clearing times, and motor control centers with enhanced safety features all contribute to hazard reduction. When evaluating equipment, designers should consider not just electrical specifications but also maintenance access, labeling visibility, and built-in safety features.

Incorporating Emergency Systems and Shutoffs

Emergency shutoffs and disconnect systems represent critical safety features that require careful integration. These systems must be intuitive, accessible during emergencies, and capable of de-energizing equipment safely without creating additional hazards.

Strategic placement of emergency shutoffs ensures workers can quickly remove power from hazardous equipment during incidents. For manufacturing equipment, this might mean emergency stops within reach of operators. For electrical rooms, it could involve exterior disconnects that allow first responders to de-energize systems without entering hazardous areas.

The design must also address the consequences of emergency shutoffs. Systems should fail safely, shutdown sequences should protect equipment from damage, and critical safety systems like emergency lighting or fire suppression should remain operational even when other systems are de-energized.

Documentation and Labeling Systems

Comprehensive documentation forms the foundation for ongoing safety. Engineering consulting for safety includes creating documentation that supports both immediate installation needs and long-term maintenance requirements.

This documentation should include detailed arc flash labels with current incident energy levels, approach boundaries, and required PPE. Single-line diagrams that clearly show system configuration, protective device settings, and coordination curves help maintenance personnel understand the systems they work on. Maintenance procedures that reflect actual system characteristics enable safe work practices.

For Atlanta-area facilities, documentation becomes especially important when working with multiple contractors or maintenance providers. Clear, comprehensive documentation ensures everyone working on electrical systems has the information needed to work safely, regardless of their familiarity with the specific facility.

Practical Steps for Implementing Integrated Design

Transitioning to integrated electrical design services requires commitment from multiple stakeholders and systematic implementation. Facilities can follow these practical steps to begin incorporating safety protocols into their design processes.

Step 1: Establish a Safety-First Design Philosophy

Integration begins with organizational commitment. Facility leadership should establish clear policies that require safety consideration at every design stage. This means setting expectations that electrical designers will coordinate with safety professionals, that budgets will include resources for safety analysis, and that project schedules will allow time for comprehensive safety planning.

For companies new to this approach, establishing a cross-functional design team helps ensure safety remains central. Include electrical engineers, safety professionals, maintenance supervisors, and operations managers in design discussions. This diverse perspective identifies safety considerations that might be missed by any single discipline.

Step 2: Conduct Baseline Safety Assessments

Before modifying existing systems or designing new installations, conduct comprehensive baseline assessments of current electrical safety. This includes arc flash assessments of existing equipment, reviews of current PPE programs, and evaluations of compliance with NFPA 70E and OSHA requirements.

These baseline assessments identify immediate safety concerns that require correction and establish benchmarks for measuring improvement. They also help prioritize design modifications based on actual risk levels rather than assumptions.

Shaw Consulting Services frequently works with Atlanta facilities to conduct these baseline assessments, providing detailed analysis of existing systems and clear recommendations for improvement through design modifications.

Step 3: Integrate Arc Flash Hazard Analysis Early

Rather than treating arc flash assessments as separate projects, incorporate hazard analysis into the design workflow. When specifying new equipment or modifying existing systems, conduct preliminary arc flash calculations to understand how changes affect incident energy levels.

This early analysis allows designers to make adjustments while changes remain inexpensive. Switching to a different breaker curve, adding fault-current-limiting features, or reconfiguring feeders might add minimal cost during design but would require extensive retrofits if hazards are discovered only after installation.

Step 4: Design for Maintenance and De-Energized Work

Throughout the design process, ask how maintenance personnel will service equipment safely. Can critical maintenance be performed with the equipment de-energized? Are disconnects accessible and clearly labeled? Do workers have adequate space to perform tasks safely?

This maintenance-focused perspective often identifies opportunities to eliminate energized work entirely. Maintenance bypasses, redundant systems, and operational flexibility that allows equipment shutdown all reduce the need for high-risk energized work.

Step 5: Develop Comprehensive PPE Programs

Work with safety professionals to develop PPE programs that align with electrical system design. Identify equipment where energized work cannot be avoided, determine appropriate PPE for specific tasks, and ensure that protection equipment is available and properly maintained.

The most effective programs use system design to minimize PPE requirements rather than relying on ever-increasing protection levels. When designers reduce incident energy levels through engineering controls, they make compliance more practical and affordable.

Step 6: Create Detailed Documentation and Training Materials

Complete the integration by developing documentation that supports long-term safety. This includes updated single-line diagrams, accurate arc flash labels, detailed maintenance procedures, and training materials that reflect actual system characteristics.

Documentation should be a living resources that evolve with the facility. When systems are modified, documentation must be updated to reflect current conditions. Regular reviews ensure information remains accurate and useful.

Long-Term Benefits: Why Integration Pays Off

Facilities that successfully integrate electrical design services with safety protocols experience benefits that extend far beyond immediate hazard reduction. These advantages compound over time, creating safer and more efficient operations.

Reduced Incident Rates and Severity

The most obvious benefit is fewer electrical incidents and reduced severity when incidents do occur. Facilities with integrated approaches typically see 60-80% reductions in electrical incidents compared to industry averages. When incidents do happen, lower incident energy levels result in less severe injuries and reduced equipment damage.

For Atlanta businesses, this translates directly to lower workers’ compensation costs, reduced insurance premiums, and improved employee morale. Workers who see their employers prioritizing safety through design demonstrate higher engagement and retention.

Simplified Compliance Management

Integrated design makes ongoing compliance far simpler. When electrical systems are designed to meet or exceed NFPA 70E requirements, facilities spend less time and resources managing compliance issues. Accurate documentation streamlines inspections, training becomes more straightforward, and regulatory reporting requires less effort.

This simplified compliance also provides protection during OSHA inspections or after incidents. Facilities that can demonstrate they have integrated safety into design decisions, conducted appropriate assessments, and implemented comprehensive programs face reduced liability and regulatory risk.

Lower Total Cost of Ownership

While integrated design might increase initial engineering costs slightly, total ownership costs decrease substantially. Facilities avoid expensive retrofits when hazards are discovered post-installation. Reduced incident rates eliminate costs associated with accidents. Simplified maintenance and lower PPE requirements reduce ongoing operational expenses.

Many Atlanta facilities have found that integrated approaches pay for themselves within 18-24 months through avoided incidents, reduced insurance costs, and eliminated retrofit expenses.

Enhanced Operational Flexibility

Systems designed with safety integration often provide greater operational flexibility. Multiple disconnects, distributed architectures, and redundant systems allow maintenance without full facility shutdowns. Clear documentation and comprehensive training enable faster response to equipment issues.

This flexibility becomes particularly valuable during expansions or modifications. Facilities with well-designed, thoroughly documented systems can integrate new equipment more easily and safely than those with ad-hoc electrical installations.

Improved Organizational Safety Culture

Perhaps the most valuable long-term benefit is improved safety culture. When employees see safety built into facility design rather than added as an afterthought, they recognize organizational commitment to protection. This recognition influences behavior, encourages reporting of hazards, and creates an environment where safety improvement is continuous.

Frequently Asked Questions

What are electrical design services, and how do they improve workplace safety?

Electrical design services involve planning, specification, and documentation of electrical systems for facilities. When integrated with safety protocols from the beginning, they improve workplace safety by reducing arc flash hazards, ensuring proper equipment spacing, incorporating emergency shutoffs, and minimizing incident energy levels before installation.

How does an arc flash assessment integrate with electrical design?

Arc flash assessments integrated with electrical design occur during the planning phase, allowing engineers to configure systems that reduce incident energy levels before equipment is installed. This includes selecting faster-acting protective devices, limiting fault current through system architecture, and specifying arc-resistant equipment, all more cost-effective during design than as retrofits.

What role does NFPA 70E training play in electrical system design?

When electrical system design considers NFPA 70E training requirements, facilities create environments where compliance is practical. This includes designing adequate working clearances, ensuring proper labeling locations, creating accessible electrical rooms, and providing documentation that supports accurate job hazard analyses.

Why is PPE planning important during the electrical design phase?

PPE planning during electrical design allows engineers to make decisions that minimize protection requirements. By considering PPE needs early, designers can incorporate maintenance switches, remote racking capabilities, and configurations that enable de-energized work, reducing the burden on workers while ensuring appropriate protection.

How can facilities begin integrating safety protocols with electrical design services?

Start by establishing a safety-first design philosophy requiring coordination between electrical engineers and safety professionals from project initiation. Conduct baseline safety assessments, integrate arc flash hazard analysis early in projects, create cross-functional design teams, and develop comprehensive documentation supporting installation and long-term maintenance.

What are the cost benefits of integrating electrical design services with safety protocols?

Benefits include avoiding expensive retrofits, reducing incident-related costs like workers’ compensation and equipment damage, lowering insurance premiums, simplifying compliance management, and reducing PPE costs. Many facilities find this approach pays for itself within 18-24 months through combined savings.

How does integrated electrical design reduce workplace accidents?

Integrated design reduces accidents by eliminating hazards before they exist through system configuration that minimizes arc flash energy, strategic emergency shutoff placement, equipment layouts facilitating safe maintenance access, selection of equipment with enhanced safety features, and clear documentation enabling safe work practices.

Moving Forward: Your Path to Integrated Safety

Integrating electrical design services with safety protocols represents a fundamental shift from reactive to proactive safety management. Rather than addressing hazards after they’ve been created, this approach prevents hazards from existing in the first place.

For facilities beginning this journey, start with your next electrical project, whether it’s new construction, expansion, or equipment replacement. Engage electrical designers and safety professionals together from day one. Establish clear safety goals alongside electrical performance requirements. Conduct preliminary hazard assessments during design rather than after installation.

The investment in integrated design services pays dividends in reduced incidents, simplified compliance, and improved operations. More importantly, it demonstrates a genuine commitment to worker safety, creating workplaces where people can perform their jobs without unnecessary electrical risks.

Shaw Consulting Services specializes in integrated electrical design services that prioritize safety throughout the Atlanta area. Our team combines electrical engineering expertise with a comprehensive understanding of NFPA 70E, OSHA requirements, and practical safety implementation. We work with facilities to develop electrical systems where safety is engineered into every component, not added as an afterthought.

Whether you’re planning new construction, upgrading existing systems, or simply want to improve electrical safety at your facility, our engineering consulting for safety services can help you achieve your goals. Contact Shaw Consulting Services today to discuss how integrated electrical design can create a safer workplace for your team.