Unplanned equipment failure isn’t just inconvenient. It’s costly, disruptive, and often preventable. For facility managers, operations teams, and safety professionals in industries like manufacturing, education, and commercial real estate, predictive maintenance has become a must-have strategy.

At Shaw Consulting Services, we work with clients throughout Atlanta and beyond who manage complex electrical systems. They’re looking for smarter, more proactive ways to ensure safety, reliability, and efficiency, without being caught off guard by unexpected issues.

In this post, we’ll explain how AI-powered thermographic scanning is redefining predictive maintenance. You’ll learn how it works, why it outperforms traditional inspections, and how it can help you detect and address issues before they cause major disruptions.

What Is AI-Powered Thermographic Scanning?

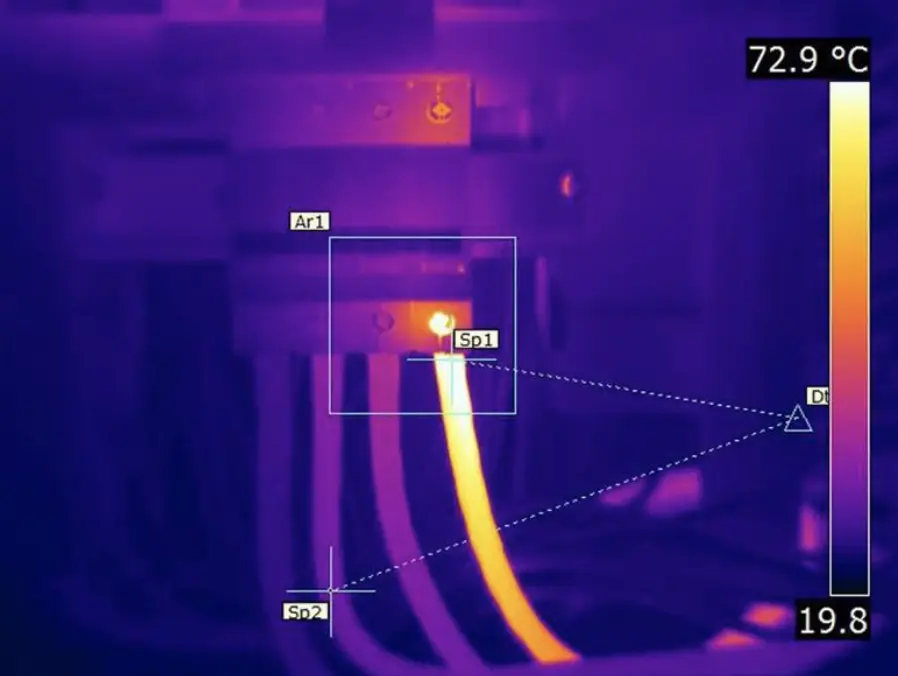

Thermographic scanning, also known as infrared imaging, uses heat signatures to spot potential problems in electrical systems. It’s a trusted, non-invasive method that helps identify risks like loose connections, overloaded circuits, and deteriorating components.

When artificial intelligence is added to the process, the results are more precise and far-reaching. AI scans and evaluates thermal data over time, learning to identify patterns and subtle shifts that might go unnoticed by the human eye. Instead of simply catching what’s overheating in the moment, AI provides early warnings by analyzing trends across multiple data points.

With this added intelligence, teams can move from routine visual checks to a more dynamic, data-driven approach.

Where Traditional Thermal Imaging Falls Short

While traditional infrared inspections are still valuable, they rely heavily on a technician’s interpretation and are often scheduled only a few times per year. This leaves long windows where small changes can escalate into serious issues.

AI-enhanced scanning solves this problem by continuously analyzing thermal data and comparing it against historical benchmarks. It learns what’s normal for your systems and flags even slight deviations, giving you a more complete and accurate picture of your facility’s condition.

This approach reduces the chance of missing problems, cuts down on costly emergency repairs, and supports smarter decision-making.

Key Benefits of AI Thermographic Scanning

Here’s how this technology can improve your predictive maintenance efforts:

- Catch issues early before they lead to downtime or safety hazards.

- Reduce repair costs by identifying small problems before they become big ones.

- Increase workplace safety by minimizing the risk of fires or arc flash events.

- Ensure compliance with NFPA 70E and other electrical safety standards.

- Improve energy efficiency by detecting electrical components that are wasting power.

- Access clear reporting that helps your team and stakeholders understand what needs attention.

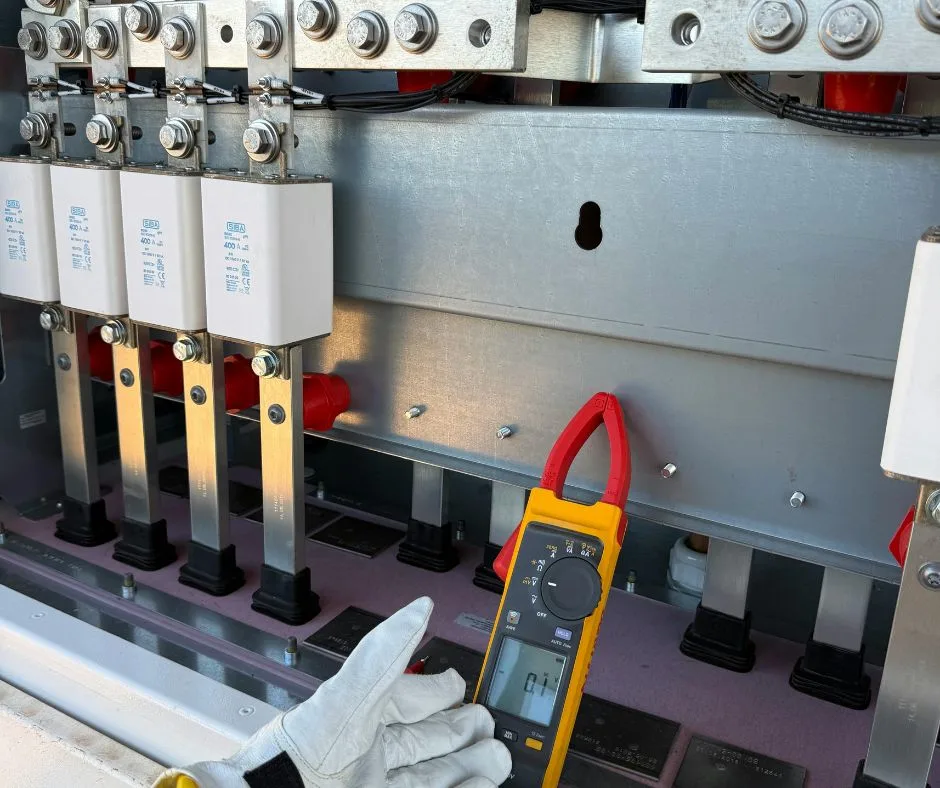

At Shaw Consulting Services, we often pair this technology with other services like Arc Flash Risk Assessments, Power Studies, and Electrical Breaker Testing to offer a full view of electrical system performance.

Why This Matters in the Atlanta Climate

Here in Atlanta, heat and humidity can intensify the wear and tear on electrical components. When systems are pushed to their limits during the warmer months, problems can develop faster than expected.

AI-powered thermographic scanning is especially useful in these conditions. It spots changes caused by environmental stress before they reach critical levels. That means better planning, fewer surprises, and more confidence in your maintenance schedule.

Who Should Consider This Technology?

AI thermal scanning is a great fit for organizations that:

- Manage large or aging electrical infrastructure

- Operate facilities with strict safety or compliance standards

- Want to reduce downtime and maintenance costs

- Need reliable insights without disrupting daily operations

If your team already conducts electrical studies or safety assessments, this is a powerful addition to your toolkit.

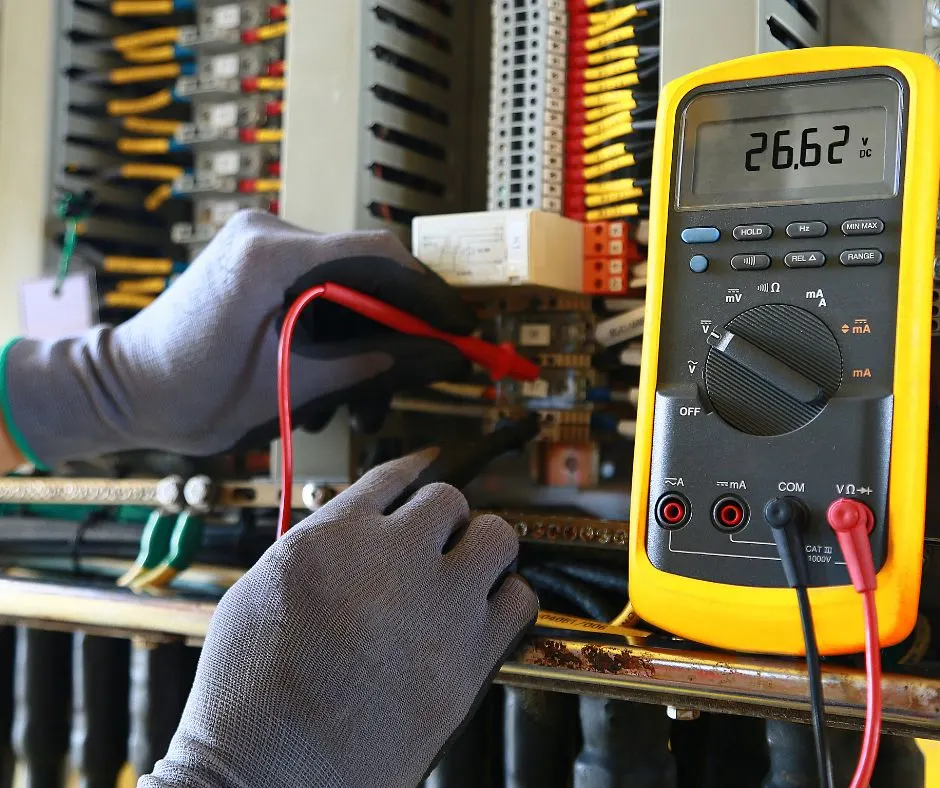

Smarter Maintenance Starts with Better Data

AI-powered thermographic scanning doesn’t replace your maintenance team—it gives them better information. It works hand-in-hand with your current strategies, whether you’re performing routine inspections, planning equipment replacements, or evaluating risks with breaker testing and arc flash studies.

Facilities that adopt this technology gain a clearer understanding of what’s happening behind the scenes. They’re able to prevent failures, extend the life of equipment, and keep their operations running smoothly.

At Shaw Consulting Services, we help teams apply this technology in ways that are cost-effective and tailored to their environment.

Proactive Maintenance Starts with Smarter Tools

Predictive maintenance is no longer a future concept. It’s here now, and AI-powered thermographic scanning is helping facilities get ahead of problems instead of reacting to them.

If your business is focused on reliability, safety, and long-term performance, this technology can make a real difference. Whether you manage a commercial property, an industrial plant, or a campus in the Atlanta area, adding smart thermal imaging to your maintenance plan is a practical, forward-thinking step.

Shaw Consulting Services is here to support that transition. We’re committed to helping our clients stay ahead with tools that work and insights that matter.