When it comes to electrical safety and maintenance, NFPA 70B and NFPA 70E are two major players. But what exactly do they cover, and how do they differ? Business owners and facility managers often hear about these standards but may not fully understand their purpose. If you’re managing electrical safety in your facility, knowing the difference can help you stay compliant and protect your employees.

In this blog, we’ll break down the key differences between NFPA 70B and NFPA 70E, explain how they affect your facility, and discuss why both are crucial for maintaining electrical safety. By the end, you’ll have a clear understanding of how these standards work together to create a safer workplace.

What is NFPA 70B?

NFPA 70B is all about electrical maintenance. This standard provides guidelines for maintaining electrical equipment to prevent failures and reduce hazards. It focuses on best practices for inspecting, testing, and servicing electrical systems to keep them in optimal condition.

Key Highlights of NFPA 70B:

Preventative maintenance strategies for electrical systems

- Scheduled Equipment Inspections: Regularly inspecting electrical panels, transformers, and circuit breakers helps identify wear and tear before it leads to failure. A structured schedule ensures that no component is overlooked.

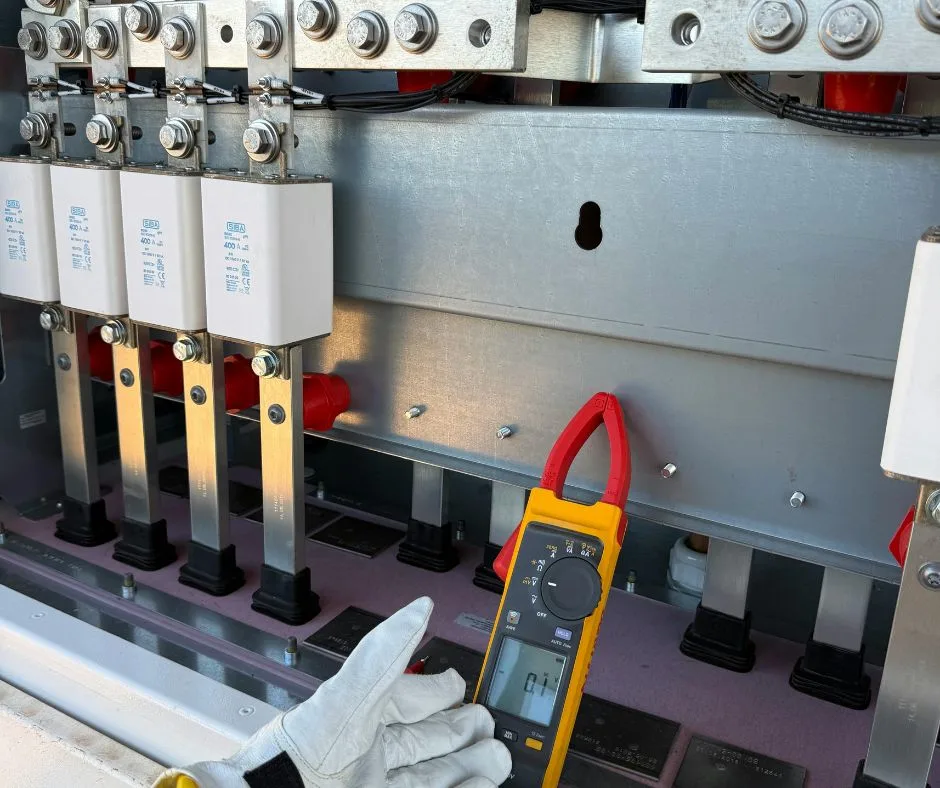

- Routine Testing Procedures: Implementing periodic testing of electrical systems, including load testing and insulation resistance checks, ensures reliability and identifies early signs of degradation.

- Proactive Component Replacement: Instead of waiting for failure, replacing aging components such as capacitors, fuses, and relays at predetermined intervals prevents costly downtime.

Recommended inspection schedules and procedures

- Annual Electrical Audits: Conducting full-system audits yearly to assess the condition of wiring, grounding, and protective devices ensures compliance with NFPA 70B guidelines.

- Infrared Thermographic Inspections: Using thermal imaging to detect overheating components before they fail minimizes the risk of fires and electrical breakdowns.

- Breaker and Switchgear Maintenance: Cleaning, lubricating, and testing switchgear components periodically extends their lifespan and enhances system performance.

Guidelines for infrared thermography and thermographic scanning

- Identifying Hot Spots: Infrared scans highlight areas of excessive heat, indicating potential failures due to loose connections, overloaded circuits, or failing components.

- Comparative Data Analysis: Tracking temperature changes over time helps predict and prevent future electrical failures.

- Preventive Action Implementation: Based on thermographic findings, necessary repairs and adjustments can be made before issues escalate into costly breakdowns.

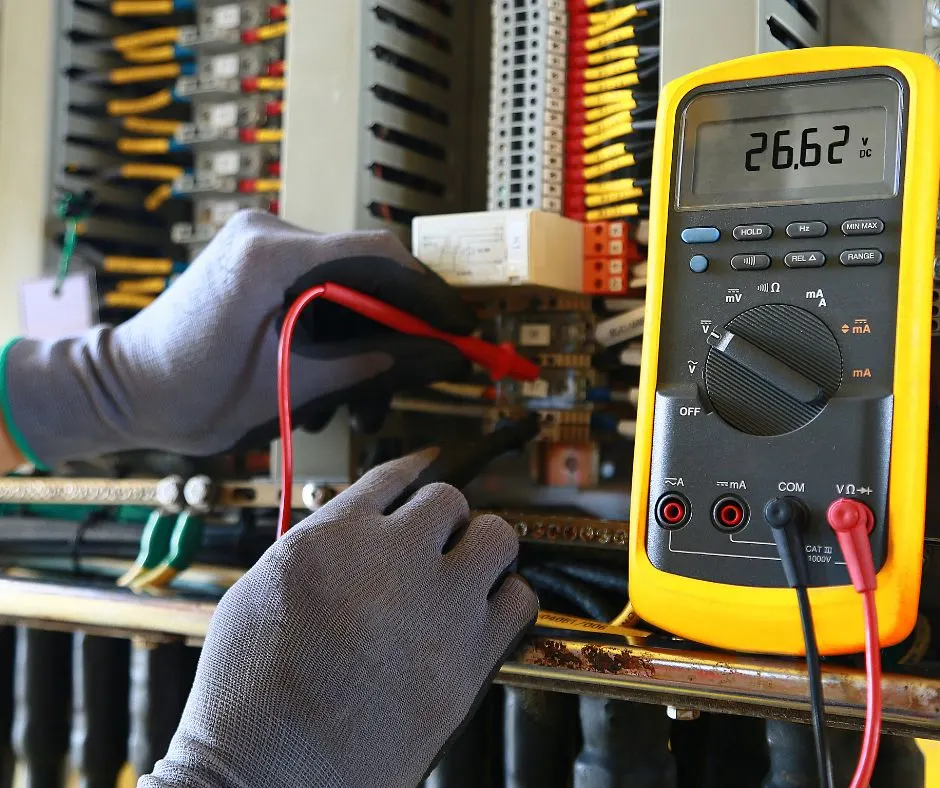

Methods for assessing electrical metering performance

- Voltage and Current Monitoring: Ensuring metering accuracy through calibration and comparison with known reference measurements.

- Data Analytics Integration: Utilizing smart meters that collect real-time energy consumption data helps optimize energy usage and detect anomalies.

- Fault Detection and Diagnostics: Advanced metering systems can pinpoint irregularities such as voltage sags, harmonics, and power factor inefficiencies.

Best practices for documentation and record-keeping

- Digital Maintenance Logs: Keeping electronic records of inspections, repairs, and replacements ensures traceability and compliance with safety regulations.

- Historical Data Analysis: Reviewing past maintenance logs can help identify patterns that lead to frequent failures and guide improvements in maintenance strategies.

- Compliance Tracking: Ensuring records align with NFPA 70B and NFPA 70E guidelines to facilitate safety audits and regulatory adherence.

Strategies for improving electrical system longevity and efficiency

- Energy Efficiency Upgrades: Implementing high-efficiency transformers, LED lighting, and power factor correction devices reduces energy waste and extends equipment life.

- Load Balancing Techniques: Ensuring even distribution of electrical loads across circuits minimizes stress on components and prevents premature failure.

- Predictive Maintenance Strategies: Using AI-driven analytics and IoT-enabled sensors to anticipate equipment failures before they occur, ensuring continuous system reliability and performance.

By following NFPA 70B, businesses can prevent costly downtime and improve overall electrical reliability.

What is NFPA 70E?

NFPA 70E focuses on electrical safety in the workplace. It outlines procedures for preventing electrical hazards like arc flash incidents and electric shock. Unlike NFPA 70B, which is maintenance-focused, NFPA 70E provides a framework for how workers should handle electrical systems safely.

Key Highlights of NFPA 70E:

- Arc flash assessment and safety measures: This includes conducting thorough arc flash studies to determine potential hazards and implementing strategies to minimize risks. Proper signage, barrier implementation, and worker awareness programs are also part of arc flash safety measures.

- Lockout/Tagout (LOTO) procedures: Ensuring safe isolation of electrical equipment before maintenance or repairs prevents unexpected energy releases. LOTO procedures involve clear identification, tagging, and proper training for employees handling electrical systems.

- Required NFPA 70E training for employees working with electrical systems: Training covers hazard awareness, risk assessment, safe work procedures, and emergency response techniques. Employees learn how to identify potential dangers and take necessary precautions to prevent accidents.

- Personal protective equipment (PPE) requirements: PPE includes insulated gloves, flame-resistant clothing, face shields, and other protective gear designed to safeguard workers from electrical hazards. Employers must ensure PPE is appropriate for the level of exposure.

- Emergency response protocols for electrical accidents: Businesses must have clear procedures in place for responding to electrical emergencies, including first aid training, quick access to medical support, and clear guidelines for reporting incidents.

- Safe work practices and hazard risk categories: NFPA 70E categorizes electrical hazards based on risk levels and provides guidelines for mitigating risks, including safe work distances, proper tool usage, and ensuring compliance with best safety practices.

The Key Differences Between NFPA 70B and NFPA 70E

| Feature | NFPA 70B | NFPA 70E |

| Focus | Electrical maintenance | Workplace electrical safety |

| Purpose | Prevent failures | Protect workers from electrical hazards |

| Covers | Inspections, thermography, metering | Arc flash safety, LOTO, PPE |

| Compliance | Recommended best practices | Required for OSHA compliance |

| Documentation | Maintenance logs and reports | Risk assessments and safety audits |

Why Both Matter for Your Business

While they serve different purposes, NFPA 70B and NFPA 70E work together to create a comprehensive electrical safety plan. Proper maintenance (NFPA 70B) reduces the risk of electrical hazards, while workplace safety procedures (NFPA 70E) ensure employees are protected when working with electrical systems.

At Shaw Consulting Services, LLC, we help businesses implement both standards effectively. From electrical metering solutions to NFPA 70E training, we ensure that your facility remains safe and compliant.

The Impact of Compliance on Business Operations

Implementing NFPA 70B and NFPA 70E isn’t just about following regulations—it directly impacts business operations. By adhering to these standards, businesses can:

- Improve workplace safety and reduce the risk of electrical injuries

- Avoid costly equipment failures and downtime

- Maintain compliance with OSHA and other regulatory bodies

- Improve insurance eligibility and lower premiums

- Enhance overall energy efficiency and system performance

Think About It

Understanding the differences between NFPA 70B and NFPA 70E is essential for keeping your facility safe and efficient. Whether you’re focusing on electrical maintenance or workplace safety, both standards play a crucial role in protecting your business and employees. Investing in compliance today ensures a safer, more efficient future for your facility.

If you need expert guidance in implementing NFPA 70B and NFPA 70E, Shaw Consulting Services, LLC is here to help. Contact us today to ensure your facility is fully compliant and operating at peak efficiency!