If you’re managing an electrical engineering project, safety is probably always on your mind. One of the biggest risks in electrical work is the potential for an arc flash. These powerful electrical explosions don’t just cause equipment damage—they pose serious risks to anyone nearby. That’s why an arc flash risk assessment should be a top priority.

In this post, we’ll explain why arc flash risk assessments are critical for any electrical project, how they work, and the benefits they offer, from preventing accidents to saving on costs.

What is an Arc Flash?

An arc flash is an intense burst of electrical energy caused by a fault or short circuit in an electrical system. When an arc flash happens, the energy released is powerful enough to cause serious burns, damage hearing and vision, and even result in fatal injuries. Temperatures during an arc flash can reach up to 35,000 degrees Fahrenheit—hotter than the surface of the sun.

Why Arc Flash Risk Assessments Matter

Arc flash risk assessments aren’t just a good idea; they’re a critical safety measure. By conducting an arc flash assessment, you’re identifying potential hazards and understanding what needs to be done to protect everyone involved.

This assessment provides essential data, including:

- The incident energy level of equipment.

- The required Personal Protective Equipment (PPE).

- Safe working distances to minimize risk.

- Potential system vulnerabilities.

With this information, you can set up protocols and procedures to reduce the chances of an arc flash and provide your team with the knowledge they need to work safely.

How an Arc Flash Assessment Benefits Electrical Engineering Projects

Let’s be real—no one wants delays, costly repairs, or, worse, injuries. Arc flash assessments offer multiple benefits, including:

- Enhanced Safety: The assessment identifies where hazards are likely to occur, allowing you to reduce risks and create a safer work environment.

- Regulatory Compliance: Following NFPA 70e and OSHA guidelines is essential, and arc flash assessments help ensure your project meets these safety standards.

- Reduced Downtime and Costs: By identifying risks ahead of time, you avoid unexpected breakdowns, which can disrupt your project timeline and lead to extra costs.

- Improved Liability Management: In the event of an incident, having conducted a thorough risk assessment shows that your company takes safety seriously, which can help reduce liability.

Key Components of an Arc Flash Risk Assessment

An arc flash assessment involves several steps, starting with a thorough evaluation of your electrical system. Here’s a look at the key components:

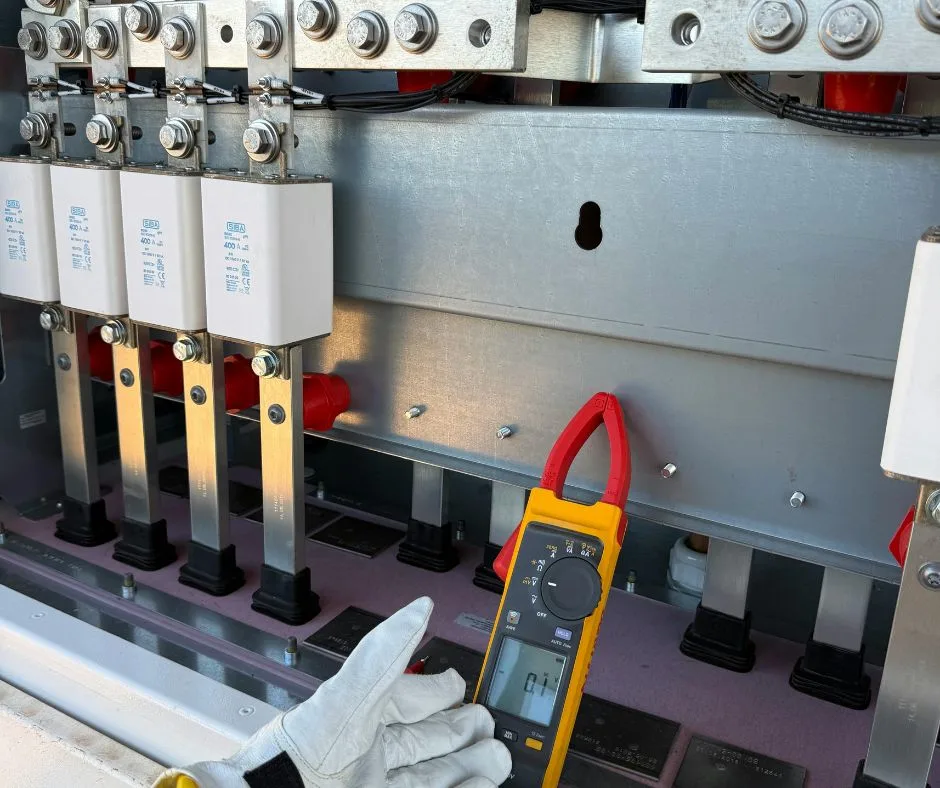

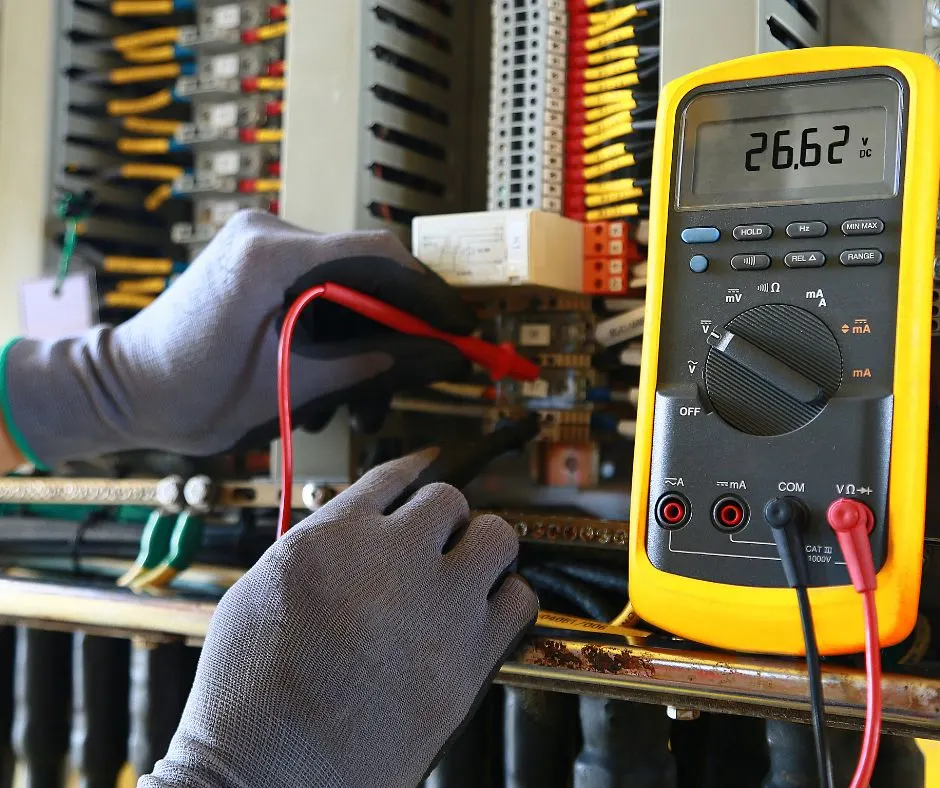

- Data Collection: The assessment begins with gathering information about your electrical system, including equipment specifications, fault currents, and system configuration.

- System Modeling and Analysis: Using the collected data, engineers create a model of the electrical system to analyze potential arc flash scenarios.

- Incident Energy Calculations: Calculations determine the energy levels workers may be exposed to in an arc flash event.

- Labeling and Documentation: Proper labels are applied to equipment to communicate PPE requirements, incident energy levels, and safe working distances.

How Often Should You Conduct an Arc Flash Assessment?

Arc flash risk assessments aren’t a one-and-done deal. It’s recommended to conduct an assessment at least every five years or whenever there are significant changes to your electrical system. If you’ve added new equipment, upgraded systems, or made structural changes, these updates could affect the arc flash risk in your facility.

Why Work with Shaw Consulting Services, LLC for Your Arc Flash Assessment?

At Shaw Consulting Services, LLC, we specialize in arc flash risk assessments that prioritize safety, accuracy, and compliance. Our experienced team will work closely with you to assess your system, identify potential hazards, and provide you with a comprehensive report and safety recommendations. We’re committed to helping you keep your team safe and your project running smoothly.

When it comes to electrical engineering projects, safety isn’t something to leave to chance. Making an arc flash risk assessment a priority means you’re taking a proactive approach to protect your team, meet regulatory requirements, and prevent costly disruptions. Contact Shaw Consulting Services, LLC today to learn more about our arc flash assessment services and keep your projects safe from start to finish.